® Copyright by ATH-Heinl GmbH & Co. KG, 2014, All rights reserved /Misprint and technical changes reserved / Issue: 12/2014

- 11 -

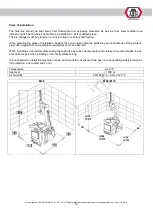

Fixing

It is recommended to fix the machine on the intended points with anchor screws M16 or corresponding anchors on the

floor.

Bore holes, pay attention in

doing so to the necessary

boring depth A and the

boring diameter of the

anchor manufacturer.

Clean the inner of the holes

Put the anchor bolts into

the holes until you reach

the bottom of the hole.

Tighten the nut with the

necessary torque specified

by the manufacturer.

Clamping thickness B

depends on flooring.

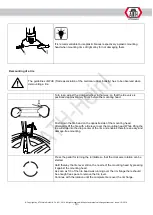

Electrical connection

Here, the general and local regulations must be observed. Therefore this step must be performed

only by an expert.

Pay attention to the correct current supply. (see technical data).

The connection should be made with a 5-phase 16 A CEE plug (

not

in scope of delivery).

The machine must be grounded.

The voltage deviation should be max. 0,9 – 1,1 times of the nominal voltage range and the frequence deviation should

be max. 0,99 – 1,01 times of the frequence range.

To guarantee this, necessary safety measures must be made.

For finishing the works the rotating direction of the motor (at 400V) must be checked.

Press the pedal which is responsable for the rotating direction of the turntable downwards.

In doing so the turntable should rotate clockwise.

If the turntable rotates in the wrong direction, change two phases in the connecting plug.