4

CL3500 Series

Installation Instructions

Cylindrical Lockset

FM237 03/19

Copyright © 2012, 2019, ASSA ABLOY Access and Egress Hardware Group, Inc. All rights reserved. Reproduction in whole

or in part without the express written permission of ASSA ABLOY Access and Egress Hardware Group, Inc. is prohibited.

For installation assistance contact Corbin Russwin

1-800-607-5703 • [email protected]

2

Door and Frame Preparation

a

Mark Door

Locate and mark horizontal center line at desired

height above floor. Fold template over edge of

door, centering on horizontal line. Mark centers

of holes at proper backset. Mark both sides of the

door.

Note

Be sure to verify backset before marking and

drilling door.

b

Drill Door

1. 2-1/8" (54mm) hole through door. Cut ANSI

tab notches as shown on template (except

CL3550 and CL3570).

2. Drill 1" (25mm) hole in edge of door. Cut

out for latch front 5/32" (4mm) deep. 1-1/8"

(29mm) wide x 2-1/4" (57mm) high. Check

latch unit for proper width front and square or

round corners (except CL3550 and CL3570).

3. Drill two (2) 11/32" (8mm) diameter holes

through door for all functions.

Caution

To avoid splintering wood doors, drill holes from

both sides.

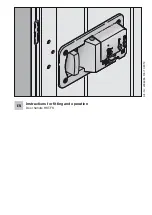

c

Install Strike

Figure 2

Mark Door

Door

Template

1

2

3

Figure 3

Drill Door

Figure 4

Install Strike

Attaching Screws

#12-24 x 1"

#8-32 x 3/4"

Optional Strike

Box

Strikes