Operation/Use

19

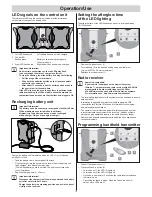

LED signals on the control unit

There are three LEDs on the control unit which provide information

on the state of charge of the battery units.

1 Left

LED

fl

ashes red

Left battery box needs to be charged

2 Centre

LED

fl

ashes green

Battery units are being charged via

the solar module

3 Right

LED

fl

ashes red

Right battery box needs to be charged

Important information!

Under certain circumstances, the red LEDs may fl ash

red even though the state of charge is suffi cient.

To stop the fl ashing, reset the battery by doing the following:

• Pull the plug of the solar module.

• Slide both the batteries outside on the track to separate

contact to the control unit.

• After about 10 seconds, push the battery units back onto

the control unit at the same time.

If the LEDs light up red even though there is suffi cient solar

radiation reaching the CISfi x module, check the module for

contamination and make sure that the lines and plugs are OK.

Recharging battery unit

Important information!

The battery units are constantly recharged by the Würth Solar

CISfi x module when solar radiation is suffi cient.

Alternatively, the battery units can also be recharged

with a charger. Only use the original charger!

Charge the battery unit immediately when the LED (1) or (3)

fl

ashes

on the control unit.

•

Take the battery unit to be charged off the track.

•

Plug the charger into the socket on the inner side of the battery unit

to be charged, then attach the mains plug.

(The left-hand battery pack is pictured, the right unit corresponds

to the illustration.)

•

Required charging time: 6–12 hours.

Important information!

Disconnect the charger from the mains power and the battery

unit after no later than 12 hours.

Charge the battery in a standing position and not in the direct

vicinity of heat sources.

Setting the afterglow time

of the LED lighting

The afterglow time of the LED lighting can be set to a value between

10–120 seconds.

2

1

•

Remove the rubber cover (1).

•

Turn the knob (2) to the desired setting using a suitable tool

(e.g. small PH0 x 3.0 mm screwdriver).

•

Reattach the rubber cover (1).

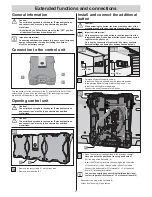

Radio receiver

HomeLink-compatible!

If your vehicle is equipped with a HomeLink system

(Version 7), our operator and radio receiver with 868.6 MHz

are compatible. Another radio frequency (40.685 or

434.42 MHz) must be used with older HomeLink systems.

For information see: http://www.eurohomelink.com

•

The local safety regulations for the system must be observed to ensure

safe operation.

•

Information is available from electrical utility companies, VDE

(Association for Electrical, Electronic & Information Technologies)

and professional associations.

•

The operator is not protected against interference caused by other

telecommunications equipment or devices (e.g. wireless systems

which are being operated properly in the same frequency range).

•

Replace the handheld transmitter unit's batteries if you experience

reception problems.

Programming handheld transmitter

2

4

3

1

5

•

Take off the rubber cover (1).

•

Press the Teach-in button (2).

– 1x for channel 1; the LED (3) lights up.

– 2x for channel 2; the LED (4) lights up.

– If no code is sent within 10 seconds, the radio receiver switches

to Normal mode.

– Cancelling the teach-in mode: Press the Teach-in button (2)

until no more LEDs are lit.