K Connector

â

Microstrip to K Female

Sparkplug Connector

Part Numbers:

K102F/K102F-HT

1. Tools And Materials

The following tools and materials are needed to install

the K102F/K102F-HT Flange Mount Connector in a

mounting hole on a housing. Equivalent tools may be

used if the recommended tools are not available.

Name

Vendor and Model/Part

Number

Hot Plate

H2155,

Micro Hot Plate,

Thermolyne, Baxter Scien-

tific Products

Step Drill Kit

01-104 or 01-108

Anritsu Co.

Torquing Tool

01-105A

Anritsu Co.

Support Bead

Holding Fixture

01-103

Anritsu Co.

Solder, 62% tin,

0.50 mm diameter

rosin core

SN62

Kester Co.

or AuSn

Rosin Flux

135, Kester Co.

Cleaning Fluid

isopropyl alcohol

2. Machining Dimensions

Machining dimensions for the mounting hole required

for installation of the microstrip to K female flange

mount connector are provided in Figure 5 on the re-

verse side.

CAUTION

The four holes shown in Note 2 of Figure 5

must be concentric within

±

0.038 mm. If they

are not, connector performance will be de-

graded. To make this required concentricity

easier to achieve, custom-made drill-bit kits,

Models 01-104 and 01-108, are available from

Anritsu.

3. Fabrication Instructions

Fabrication instructions for the sparkplug connector

assembly are provided below. Figures 1 and 2 identify

the connector parts. Refer to these figures while per-

forming the following steps.

a. Install the microstrip into the housing. Refer to

Figure 3 for dimensional tolerances around the

glass bead.

b. Set the hot plate to 200

° ±

10

°

C for SN62, or 310

°

±

10

°

C for AuSn solder.

c. Flux the glass bead and insert it, long-end first,

into the 01-103 Glass Bead Holding Fixture (Fig-

ure 4).

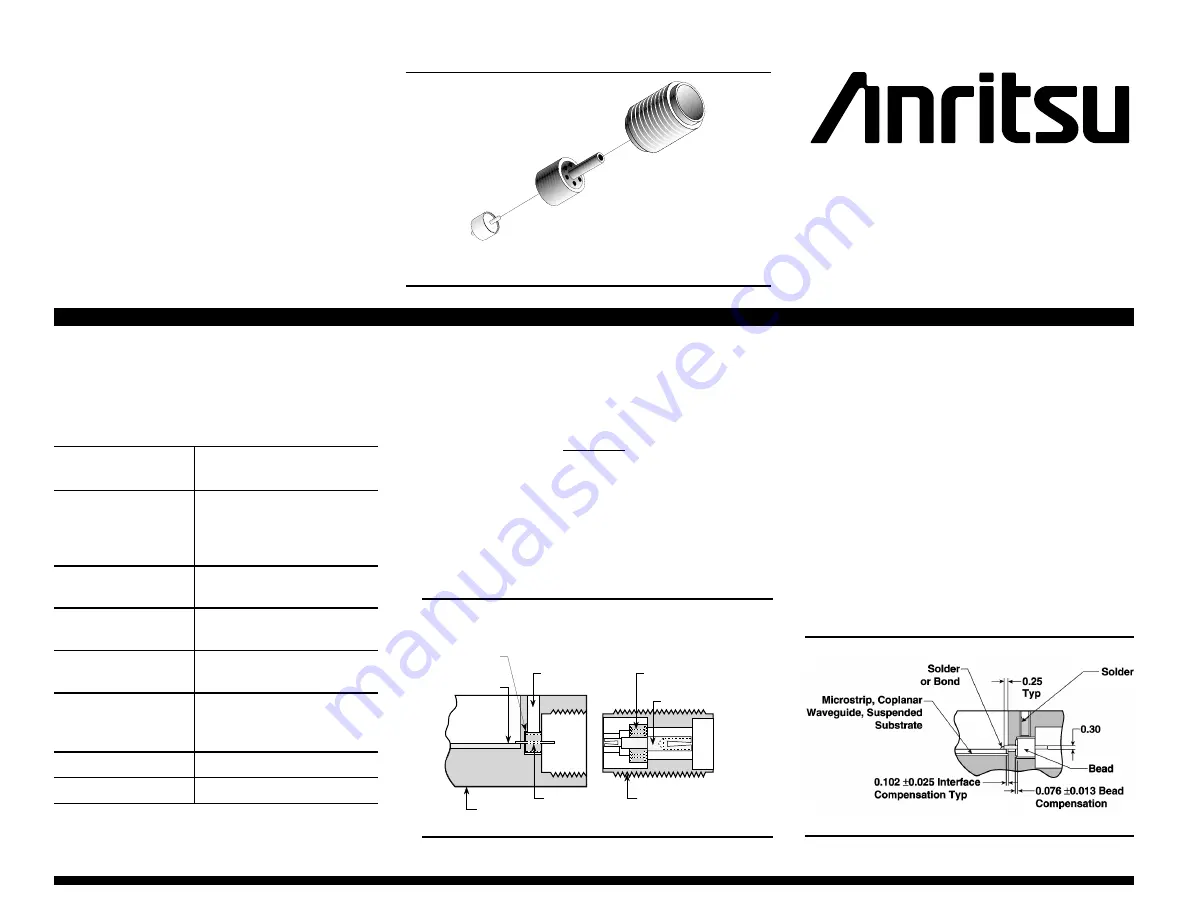

Backside

Interface

Center Conductor

Support Bead

Soldering

Access Hole

Center Conductor

Glass

Bead**

Housing

Sparkplug

Microstrip

Figure 2.

K Connector Sparkplug Assembly

Figure 3.

Glass Bead Installation

Glass

Bead**

Center Conductor

and Support

Bead Assembly

Sparkplug

Figure 1.

Sparkplug Connector

(** not supplied)