- 44 -

Gap Black

Black Mark

Continuous

Preprint

Gap

Black Mark

Auto

Fixed

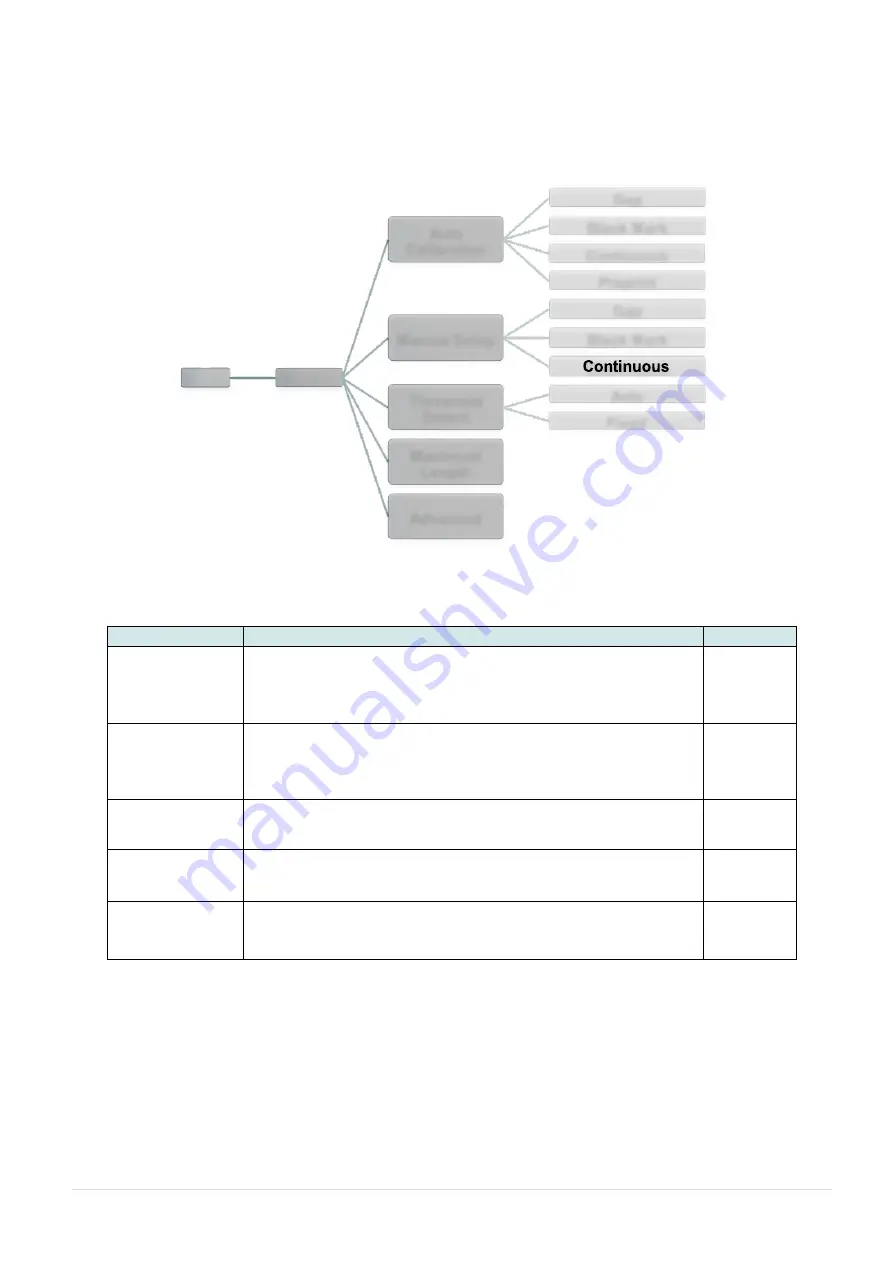

6.4

Sensor

This option is used to calibrate the selected sensor. We recommend calibrating the

sensor before printing after changing the media.

Menu

Sensor

Auto

Calibration

Manual Setup

Threshold

Detect

Maximum

Length

Item

Description

Default

Auto

Calibration

This option is used to set the media sensor type and

calibrate the selected sensor automatically. Printer will feed

2 to 3 gap labels to calibrate the sensor sensitivity

automatically.

N/A

Manual setup

In case “Automatic” cannot calibrate the media, please use

the

“Manual” function to set the paper length and Gap/B-

line size then scan the backing/mark to calibrate the sensor

sensitivity.

N/A

Threshold

Detect

This option is used to set sensor sensitivity in fixed or auto.

Auto

Maximum

Length

This option is used to set the maximum length for label

calibration.

254 mm

Advanced

This function can set the minimum paper length and

maximum Gap/B-line length for auto-calibrating the

sensor

s’ sensitivity.

0 mm

Advanced