IMPORTANT INFORMATION

•

The shipment should be thoroughly inspected as soon as it is received. Any freight

damage or missing items must be noted on the freight bill before signing and reported

to the freight carrier with a freight claim established. Buyer should claim the

compensation from the freight carrier if any damage happens to the equipment during

shipping. Please refer to our website for detailed shipping policies and procedures.

•

Make sure you have additional help or heavy-duty lifting equipment when unloading and

assembling the machine.

•

Read and understand this installation and operation manual entirely before attempting

to install or operate this machine. Keep this manual near the product for future

references. Make sure all operators read this manual.

•

This Wheel service machine should only be operated by authorized personnel. Keep

children and untrained personnel away from the machine.

•

Do not make any modifications to this machine; this voids the warranty and increases

the chances of injury or property damage.

•

Do not use the machine while tired or under the influence of drugs, alcohol, or

medication

•

Manufacturer or distributor assumes no responsibility for loss or damage of any kind,

expressed or implied, resulting from improper installation or use of this machine. Always

use professional installation companies.

•

All persons using the equipment must be responsible, qualified, and carefully follow the

operation and safety guidelines contained in this manual.

•

The machine should be installed in a place close to the main power source and

compressed air system.

•

Install the machine on the smooth concrete ground or other ground with hard flooring. 4

sets of anchor bolts can be used to fasten the machine onto the ground to avoid

vibration and noise.

•

Leave enough space for the operation and maintenance of the machine. The space

should be no less than 1M in front and on the two sides of the machine, 0.5M behind it so

that operation on different parts shall not be hindered.

•

If the machine has to be installed outdoors, a protective shelter should be built.

•

All wiring must be performed by a licensed, certified Electrician.

•

Do not perform any maintenance until the main electrical power has been disconnected

from the machine and cannot be re-energized until all procedures are complete.

•

Do not put the equipment in a place with high temperature or moisture, or near the

heating system, water tap, air-humidifier, or chimney.

•

Do not put the equipment near the window with sunlight. Protect the unit with a curtain

or shield if necessary. Never operate the machine in a place with flammable gas.

•

Avoid lots of dust, ammonia, alcohol, thinner, or spraying binder.

•

Use appropriate equipment and tools, protective and safety equipment, including

eyeglasses, earplugs, and work boots. Pay special attention to the marks on the machine.

Do not touch or approach the moving parts by hand during operating.

•

Do not remove the safety device or keep it from working properly.

•

All information in this manual is believed to be correct at the time of publication. The

design, material, and specifications are subject to change without notice.

Summary of Contents for AM-TC10626LA

Page 1: ...PLEASE READ THE PRODUCT MANUAL ENTIRELY BEFORE INSTALLING OR OPERATING THE LIFT ...

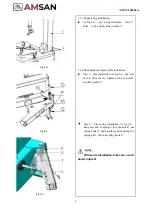

Page 22: ...Fig 34 21 AM TC10626LA 9 1 Column assembly 9 Exploded drawings ...

Page 23: ...Fig 35 22 AM TC10626LA 9 2 Turntable assembly ...

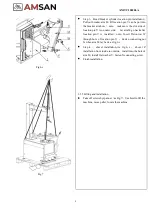

Page 24: ...Fig 36 22 AM TC10626LA 9 3 Gearbox motor assembly ...

Page 25: ...24 AM TC10626LA 9 4 Body assembly Fig 37 ...

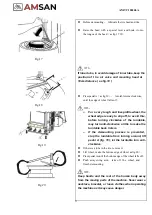

Page 26: ...25 AM TC10626LA 9 5 Bead Breaker Cylinder Breaker Arm Assembly Fig 38 ...

Page 27: ...26 AM TC10626LA 9 6 Quick inflating system Optional Fig 39 ...

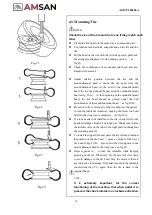

Page 28: ...27 AM TC10626LA 9 7 Simple left help arm Optional Fig 40 INSTALL ...

Page 41: ...40 AM TC10626LA Appendix 1 Electrical Diagram Fig 40 Fig 41 ...