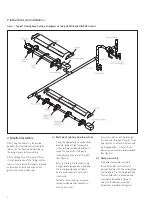

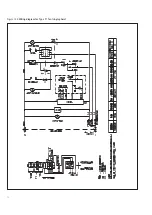

The Ambi-Rad Herringbone HB combined

manifold system may consist of either ‘U’

tube or linear heaters, linked into a common

aluminium manifold system, which in

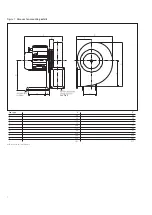

turn is coupled to one hot gas vacuum

fan to ‘evacuate’ the products of

combustion to atmosphere via a flue

system.

This document should be used in

conjunction with the specific product

installation manual i.e AR or Optima Series.

Please refer to the design manual 042/93

to ensure correct manifold design.

The following appliances are tested and

certified by an accredited test house for

use on natural gas and propane:

AR Series BG/EC – 87/95/214

Optima BG/EC – 87/95/308

The system is controlled via an Ambi-Rad

black bulb thermostat whose controller

is housed in a lockable cabinet with fan

starter for Type ‘0’ fan only and time switch.

The Ambi-Rad Herringbone HB combined

manifold system layout should be designed

to be as compact as possible with the final

connection to the hot gas vacuum fan

approximately central in the manifold

system. Please refer to document Ambi-Rad

Herringbone design manual 042/93.

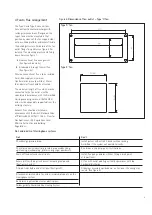

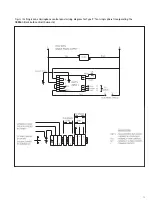

The manifold system should be arranged

to fall slightly in the direction of the hot

gas vacuum fan. This ensures that any

condensation formed in the manifold

on cold start and cool down is not trapped

or allowed to drain back into the heater unit

and will flow towards the condensate trap

located at the vacuum fan end of the

manifold system. (See figure 8a for

condensate trap arrangement)

The exhaust flue should be adequately

supported from the building structure and

installed in accordance with the British

Standard Code of Practice – Flues for Gas

Appliances, Local and Ministry Authorities

and Building Regulations. Alternatively, a

telescopic through the wall discharge duct is

available for either Type ‘0’, or Type ‘2’ fan

(available from Ambi-Rad).

Ambi-Rad will, upon receipt of a proposed

drawing showing a Herringbone system,

check the pressure drop of the manifold

system to ensure it does not exceed the hot

gas vacuum fan design criteria.

1.1 Standards

The Ambi-Rad heater must be installed

in accordance with the relevant

provisions of the Gas Safety

(Installations and Use) Regulations 1984

(as amended). Due account should also

be taken of any obligations arising from

the Health and Safety at Works etc. Act

1974. In addition the installation must

be carried out in accordance with the

current I.E.E. Regulations. The Building

(Standards) (Scotland) Consolidation

Regulations, the requirements of BS

5440:Part 1:1990, BS 6891:1998, BS

6896:1991 and any other relevant British

Standards and Codes of Practice.

1.2 Ventilation requirements

Permanent ventilation is required as

follows:

Natural ventilation

(preferably at low level)

Up to and including 60kW - 4.5cm

2

/kW,

over 60kW - 270cm

2

+ 2.25cm

2

/kW

in excess of 60kW total input.

Forced ventilation

Minimum proven air flow –

2.35m

3

/h per kW of total rated input.

For detailed information please refer

to Ambi-Rad design manual and/or

BS 6896:1991, Installation of Gas Fired

Overhead Radiant Heaters for Industrial

and Commercial Heating.

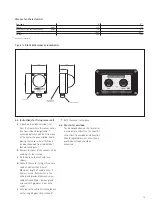

1 General arrangement of

Ambi-Rad Herringbone

2