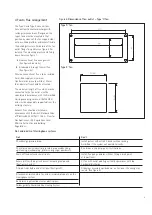

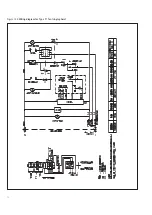

Figure 10 Damper settings

5 Commissioning

Inspect installation and ensure it has been

carried out in accordance with these

instructions.

Ensure that electrical and gas supplies are

isolated.

The gas supply should be purged and

tested for soundness in accordance with the

British Standard BS 6891:1998,

BS 7671:1992, IGE/UP/2 and any other

British Standards and Codes of Practice.

Ensure that the settings of any time switch

and thermostat are such that the heating

system will be required to operate (or put

the mode switch to ‘constant’).

Before attempting to start up the heating

system it is essential to perform the

preliminary balancing of the vacuum level at

each burner unit.

Isolate each heater unit by unplugging each

electrical connector and closing each gas

isolating valve.

Heater type

Damper setting when hot (mbar)

Heater type

Damper setting when hot (mbar)

AR

13

SHN/

22

1.7

ARE

13

SHN/

22

1.1

AR

13

SHP/

22

1.7

ARE

13

SHP/

22

1.1

AR

22

SHN/

27

1.4

ARE

22

SHN/

27

1.1

AR

22

SHP/

27

1.4

ARE

22

SHP/

27

1.1

AR

22

SHN/

32

1.4

ARE

22

SHN/

32

1.1

AR

22

SHP/

32

1.4

ARE

22

SHP/

32

1.1

AR

22

SHN/

36

1.4

ARE

22

SHN/

36

1.1

AR

22

SHP/

36

1.4

ARE

22

SHP/

36

1.1

AR

22

SHN/

39

1.4

ARE

22

SHN/

39

1.1

AR

22

SHP/

39

1.4

ARE

22

SHP/

39

1.1

AR

35

SHN/

33

1.5

ARE

35

SHN/

33

1.2

AR

35

SHP/

33

1.5

ARE

35

SHP/

33

1.2

AR

35

SHN/

42

1.2

ARE

35

SHN/

42

1.0

AR

35

SHP/

42

1.7

ARE

35

SHP/

42

1.0

AR

35

SHN/

51

1.0

ARE

35

SHN/

51

1.0

AR

35

SHP/

51

1.5

ARE

35

SHP/

51

1.0

AR

40

SHN/

42

1.6

ARE

40

SHN/

42

1.4

AR

40

SHP/

42

1.4

ARE

40

SHP/

42

1.4

AR

45

SHN/

50

1.9

ARE

45

SHN/

50

1.6

AR

45

SHP/

50

2.0

ARE

45

SHP/

50

1.6

AR

45

SHN/

60

2.0

ARE

45

SHN

/60

1.9

AR

45

SHP/

60

2.3

ARE

45

SHP/

60

1.6

AR

50

SHN/

50

1.9

ARE

50

SHN/

50

1.8

AR

50

SHP/

50

2.0

ARE50SHP/50

2.3

AR

50

SHN/

60

2.0

ARE

50

SHN/

60

1.8

AR

50

SHP/

60

2.3

ARE50SHP/60

2.3

N & P refer to natural gas or propane respectively.

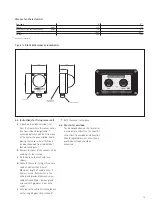

Adjust the damper at exit of each heater

using a 4mm hexagon wrench in the M8

locking screw. Observing the vacuum

reading using a ‘U’ tube manometer

connected to the vacuum test point (see

figure 4) set each damper in turn to give a

hot conditions reading as below.

Referring to each unit

Open isolating valve and test gas

connections for soundness using leak

detecting solution. Remove the combustion

chamber cover plate by unscrewing the

fixing screws. Take care not to damage the

sealing gasket. Inspect the burner and

electrode assemblies ensuring these are

securely fixed and all electrical connections

securely made. Replace the cover plate

ensuring that the sealing gasket is correctly

positioned and the screws are fully

tightened. The heater will not operate until

this plate is refitted.

Remove the safety control housing cover

plate by unscrewing the securing screws

and folding down/lifting off the plate.

Ensure all internal components are securely

fixed and all connections securely made.

Reinsert the electrical connector to the

burner control assembly.

To allow the heater to start up it is

necessary to switch off the whole system

at the time switch or manual switch and

allow the fan to stop completely before

switching on again. At this point the

individual heater unit will start up with

the following sequence.

The red

mains on

lamp will illuminate and

the main fan will start to run. Safe-start

checks are carried out automatically. After

the fan has run up to full speed and a

satisfactory vacuum condition has been

established at the burner, a purge period of

approximately 9 seconds will commence.

At the end of the purge period the ignition

sequence will commence. The spark ignition

will be energised producing a spark at the

ignition electrode. The gas solenoid valve

is energised and will open.

9