Cleaning, maintenance and repair

12.17

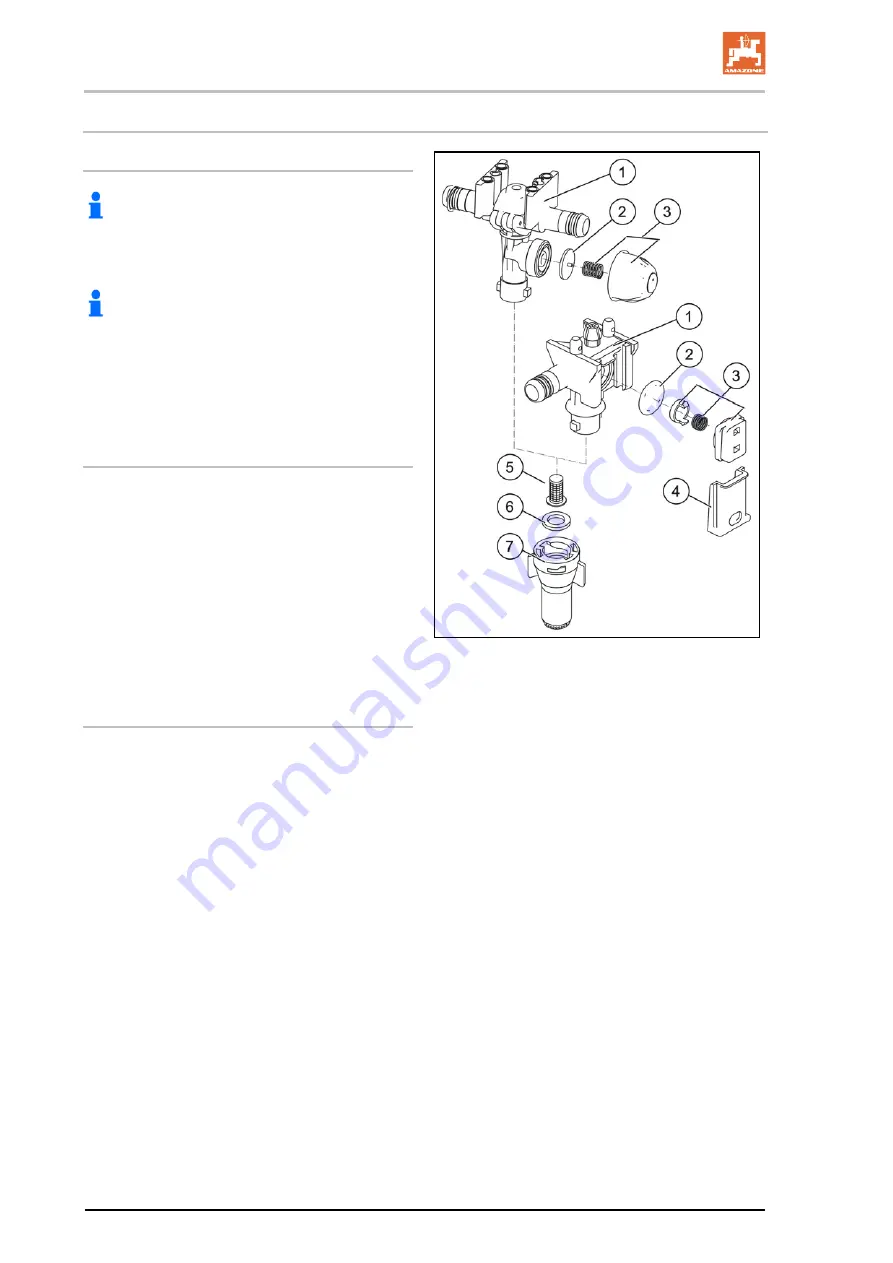

N Nozzles

Fitting the nozzle

Different nozzle sizes are marked with bayo-

net nuts of different colours.

1. Insert the nozzle filter (5) into the nozzle

body from below.

The nozzle is located in the bayonet nut

2. Press a rubber seal (6) above the nozzle

into the seat for the bayonet nut.

3. Turn the bayonet nut on the bayonet con-

nection up to the stop.

Removing the diaphragm valve if the nozzle

is dripping

Deposits on the diaphragm seat in the nozzle

body cause dripping after the nozzle has been

switched off.

1. Remove the spring element (3).

2. Take out the diaphragm (2).

3. Clean the diaphragm seat.

4. Check the diaphragm for cracks.

5. Reinstall the diaphragm and spring ele-

ment.

Checking the nozzle shutter

From time to time, check the seating of the shut-

ter (4).

To do this, insert the shutter into the nozzle body

as far as possible using moderate thumb pres-

sure.

Do not insert the shutter up to the stop when in a

new condition under any circumstances.

Fig. 176

230

BAG0021.14 05.19

Summary of Contents for UG 2200 Special

Page 237: ...Liquid circuit 13 1 UG Special BAG0021 14 05 19 237 ...

Page 238: ...Liquid circuit 13 2 UG Super 238 BAG0021 14 05 19 ...

Page 242: ...Spray table Fig 182 242 BAG0021 14 05 19 ...

Page 251: ...Spray table BAG0021 14 05 19 251 ...

Page 252: ......