Cleaning, maintenance and repair

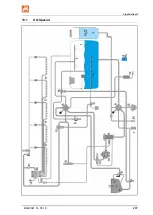

Replacing the piston diaphragm

•

Ensure the correct position for the recesses and/or holes on the

hydraulic cylinders.

•

Secure the piston diaphragm (Fig. 173/8) with a washer disc and

a screw (Fig. 173/11) on the piston (Fig. 173/9), so that the rim

shows on the cylinder head side (Fig. 173/7).

•

Always tighten the nuts (Fig. 173/1,2) in a crosswise fashion

using the specified torque. Improper tightening of the screws

causes warping, which results in leaks.

1. Undo the screw (Fig. 173/11) and remove the piston diaphragm

(Fig. 173/8) and the washer disc from the piston (Fig. 173/9).

2. If the piston diaphragm has been punctured, drain the oil/spray

liquid mixture from the pump housing.

3. Remove the hydraulic cylinder (Fig. 173/10) from the pump

housing.

4. Clean the pump housing by flushing it thoroughly with diesel oil

or paraffin.

5. Clean all sealing faces.

6. Insert the cylinder (Fig. 173/10) back into the pump housing.

7. Fit the piston diaphragm (Fig. 173/8).

8. Mount the cylinder head (Fig. 173/7) on the pump housing and

tighten the screws (Fig. 173/6) an equal amount in a crosswise

fashion.

Use adhesive for medium tight screw connections for the screw

connection!

9. After testing and cleaning, fit the valve groups (Fig. 173/5).

10. Insert new O-rings.

11. Mount the suction (Fig. 173/3) and pressure port (Fig. 173/4) on

the pump housing.

12. Tighten the nuts (Fig. 173/1,2) in a crosswise fashion using a

torque of

11 Nm

.

12.14

Calibrate the flow meter

For this purpose, observe the operating manual Software ISOBUS

chapter "Pulses per litre".

226

BAG0021.14 05.19

Summary of Contents for UG 2200 Special

Page 237: ...Liquid circuit 13 1 UG Special BAG0021 14 05 19 237 ...

Page 238: ...Liquid circuit 13 2 UG Super 238 BAG0021 14 05 19 ...

Page 242: ...Spray table Fig 182 242 BAG0021 14 05 19 ...

Page 251: ...Spray table BAG0021 14 05 19 251 ...

Page 252: ......