Cleaning, maintenance and repair

12.13.5 Checking and replacing piston diaphragms (workshop work)

•

At least once a year, check that the piston diaphragm (Fig.

173/8) is in perfect condition by removing it.

•

Pay attention to the respective installation positions of the valves

on the suction and pressure sides before removing the valve

groups (Fig. 173/5).

•

Check and replace the piston diaphragm for each piston individ-

ually. Only remove the next piston in sequence after the current-

ly removed piston has been completely checked and refitted.

•

Always swivel the piston to be checked upwards so that the oil in

the pump housing does not run out.

•

As a rule, replace all piston diaphragms (Fig. 173/8), even if only

one piston diaphragm distorted, punctured or porous.

Fig. 175

Checking the piston diaphragm

1. Remove the pump.

2. Release the screws (Fig. 173/1) and remove the tensioning

clamp (Fig. 173/2).

3. Remove the suction and pressure ports (Fig. 173/3, Fig. 173/4)

including the valve groups (Fig. 173/5).

Pay attention to the installation position of the valves on the suc-

tion and pressure sides!

4. After removing the screws (Fig. 173/6), remove the cylinder head

(Fig. 173/7).

5. Check the piston diaphragm (Fig. 173/8).

BAG0021.14 05.19

225

Summary of Contents for UG 2200 Special

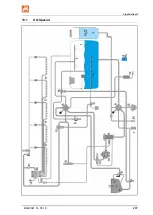

Page 237: ...Liquid circuit 13 1 UG Special BAG0021 14 05 19 237 ...

Page 238: ...Liquid circuit 13 2 UG Super 238 BAG0021 14 05 19 ...

Page 242: ...Spray table Fig 182 242 BAG0021 14 05 19 ...

Page 251: ...Spray table BAG0021 14 05 19 251 ...

Page 252: ......