G A S C O M B I T H E R M

—

I N S T A L L A T I O N M A N U A L

#MN-28676

PG

. 13

®

C O M B I T HE R M

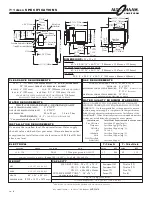

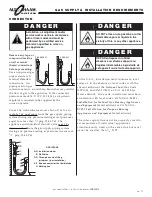

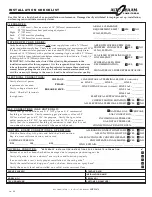

V E N T I L AT I O N & I N S TA L L AT I O N R E Q U I R E M E N T S

1.

A single gas Combitherm oven requires a minimum of

28 CFM

make-up air for natural and propane gas.

Kitchen ventilation must include a provision for an

adequate flow of fresh air for gas combustion and to

prevent a negative-pressure condition. The bottom of

the oven provides air supply access for gas

combustion and must be kept clear at all times.

DO NOT

obstruct or restrict ventilation nor the air

flow required to support combustion.

2.

DO NOT

obstruct the flow of the exhaust flue at the

top rear of the oven. It is especially critical that gas

supply piping and electrical support cord and/or

receptacle be routed away from the path of the hot

combustion fumes.

3.

Make certain the oven installation maintains adequate

air ventilation to provide cooling for electrical and gas

components. The area around the oven should be

clear of any obstructions which might retard the flow

of cooling air. Failure to observe this caution may

result in damage to the components and will void the

warranty.

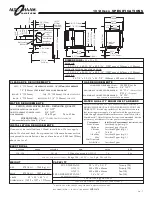

4.

This oven cannot be direct vented.

5.

Install the oven under a ventilation hood meeting all

applicable code requirements. Combustion fumes

must be vented in accordance with local, state, or

national codes.

Ventilating hoods and exhaust systems shall be

permitted to be used to vent appliances installed in

commercial applications.

Where automatically operated appliances are vented

through a ventilating hood or exhaust system equipped

with a damper or with a power means of exhaust,

provisions shall be made to allow the flow of gas to the

main burners only when the damper is open to a position

to properly vent the appliance and when the power means

of exhaust is in operation.

IN ACCORDANCE WITH

NFPA 54

COMMONWEALTH OF MASSACHUSETTS ONLY

.

An adequate ventilation system is required for commercial

cooking equipment. Information may be obtained by

writing to the National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269. When writing refer

to NFPA No. 96.

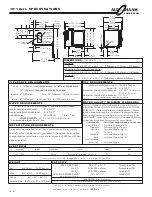

Inadequate ventilation, or failure to ensure

an adequate supply of fresh air will result in

a high ambient temperature at the rear of the

oven. An excessive ambient temperature

can cause the thermal-overload protection

device on the blower motor to trip resulting

in severe damage to the blower motor.

D A N G E R

Installation, air adjustment and/or

service work must be in accordance

with all local codes and must be

performed by a certified service

technician qualified to work on

gas appliances.

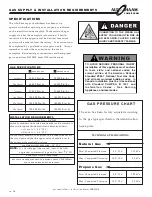

D A N G E R

FAILURE TO VENT THIS APPLIANCE

PROPERLY MAY BE HAZARDOUS TO

THE HEALTH OF THE OPERATOR.

Equipment damage, operational

problems and unsatisfactory baking

performance may also be the

consequence of improper venting.

Any damage sustained by a failure to

properly vent this oven are not

covered under warranty.

C A U T I O N

DO NOT USE CIRCULATING FANS

ON THE FLOOR. FLOOR FANS WILL

AFFECT BURNER OPERATION.

C A U T I O N

To prevent malfunction or cause

negative back draft, DO NOT obstruct

exhaust flues or attach any flue

extension that will impede proper

burner operation.