507335-01

Page 40 of 44

Issue 1624

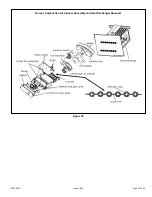

Cabinet Parts

Heating compartment access panel

Blower access panel

Top cap

Control Panel Parts

Transformer

Two-stage, variable speed integrated control

Door interlock switch

Blower Parts

Blower wheel

Blower housing

Motor

Motor electronics

Power Choke (1 hp only)

Motor mounting frame

Blower housing cutoff plate

Repair Parts List

The following repair parts are available from the local distributor. When ordering parts, include the complete furnace model

number and serial number which are printed on the rating plate located on the furnace.

All service must be performed by

a licensed professional installer (or equivalent), service agency, or gas supplier.

Heat Parts

Flame sensor

Heat exchanger assembly

Gas Manifold

Two speed combustion air inducer

Two stage gas valve

Main burner cluster

Main burner orifices

Pressure switch

Ignitor

Primary limit control

Flame rollout switch

Secondary limit

Planned Service

Fresh air grilles and louvers

(on the unit and in the room

where the furnace is installed) - Must be open and unob-

structed to provide combustion air.

Burners

- Must be inspected for rust, dirt, or signs of water.

Vent pipe

- Must be inspected for signs of water, damaged

or sagging pipe, or disconnected joints.

Unit appearance

- Must be inspected for rust, dirt, signs of

water, burnt or damaged wires, or components.

Blower access panel

- Must be properly in place and pro-

vide a seal between the return air and the room where the

furnace is installed.

Return air duct

- Must be properly attached and provide

an air seal to the unit.

The following items should be checked during an annual inspection. Power to the unit must be shut off for the service

technician’s safety.

Operating performance

- Unit must be observed during

operation to monitor proper performance of the unit and the

vent system.

Combustion gases

- Flue products must be analyzed and

compared to the unit specifications.

Problems detected during the inspection may make it

necessary to temporarily shut down the furnace until the

items can be repaired or replaced.

Instruct the homeowners to pay attention to their

furnace.

Situations can arise between annual furnace

inspections that may result in unsafe operation. For

instance, items innocently stored next to the furnace may

obstruct the combustion air supply. This could cause

incomplete combustion and the production of carbon

monoxide gas.

Summary of Contents for 80G2UH-V

Page 29: ...507335 01 Page 29 of 44 Issue 1624 ADJUSTING AIRFLOW Table 11 ...

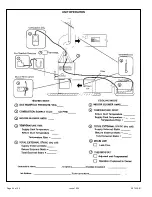

Page 41: ...507335 01 Page 41 of 44 Issue 1624 Wiring Diagram Figure 41 ...

Page 42: ...507335 01 Page 42 of 44 Issue 1624 Typical Field Wiring Diagram Figure 42 ...

Page 43: ...507335 01 Page 43 of 44 Issue 1624 Start Up Performance Check List UNIT SET UP ...

Page 44: ...507335 01 Page 44 of 44 Issue 1624 UNIT OPERATION ...