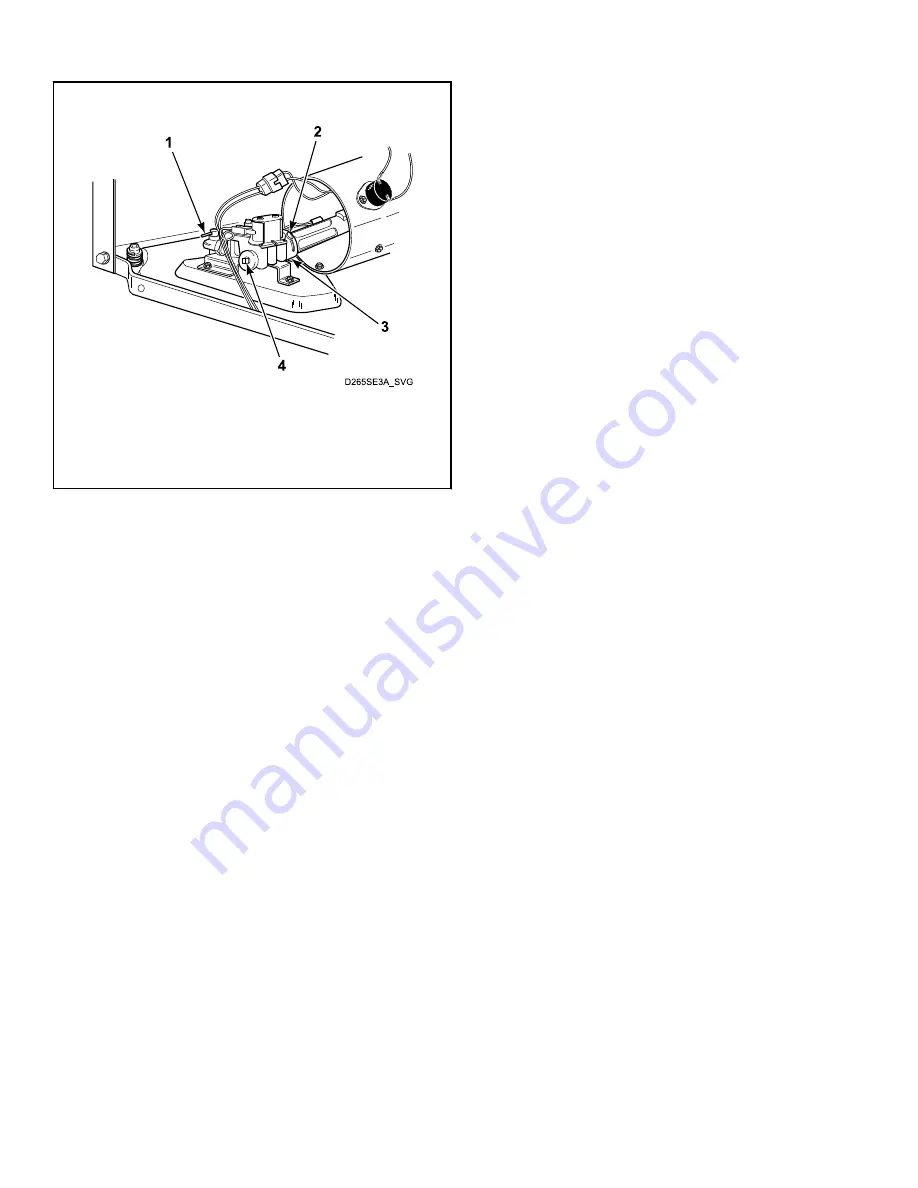

Gas Shut-Off Valve Only Applicable on Certain Mod-

els

1.

Shut-off Valve Handle

2.

Air Shutter Lockscrew

3.

Air Shutter

4.

1/8" Pipe Plug (For checking manifold pressure)

Figure 4

Adjustments

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

40

Part No. D515517ENR3