Rockwell Automation Publication SAFETY-AT140A-EN-P - May 2015

17

Safety Function: Actuator Subsystems – Stop Category 1 via the PowerFlex 525 and PowerFlex 527 Drives with Safe Torque-off

Verification and Validation Plan

Verification and validation play important roles in the avoidance of faults throughout the safety system design and

development process. ISO 13849-2 sets the requirements for verification and validation. The standard calls for a

documented plan to confirm that all of the safety functional requirements have been met.

Verification is an analysis of the resulting safety control system. The Performance Level (PL) of the safety control system is

calculated to confirm that the system meets the required Performance Level (PLr) specified. The SISTEMA software is

typically used to perform the calculations and assist with satisfying the requirements of ISO 13849-1.

Validation is a functional test of the safety control system to demonstrate that the system meets the specified requirements

of the safety function. The safety control system is tested to confirm that all of the safety-related outputs respond

appropriately to their corresponding safety-related inputs. The functional test includes normal operating conditions in

addition to potential fault injection of failure modes. A checklist is typically used to document the validation of the safety

control system.

This document uses, as an example, a SensaGuard switch for an input device. Notice that in the validation process, all of the

purposely-created faults are created at the input terminals of the Guardmaster dual-input safety relay. All of the relay’s

responses to these faults are the same as they would be using any typical input device with OSSD outputs, or an electro-

mechanical input device using the Guardmaster dual-input safety relay pulse test output feature.

Some of the SensaGuard switch’s reactions to these faults are unique to the SensaGuard switch, as some responses from

other OSSD devices might be unique to those devices.

The responses of the PowerFlex 527 drive and the PowerFlex 525 drive to faults on their STO inputs are the same.

Therefore, the following tests, using purposely-created faults, are appropriate for either drive.

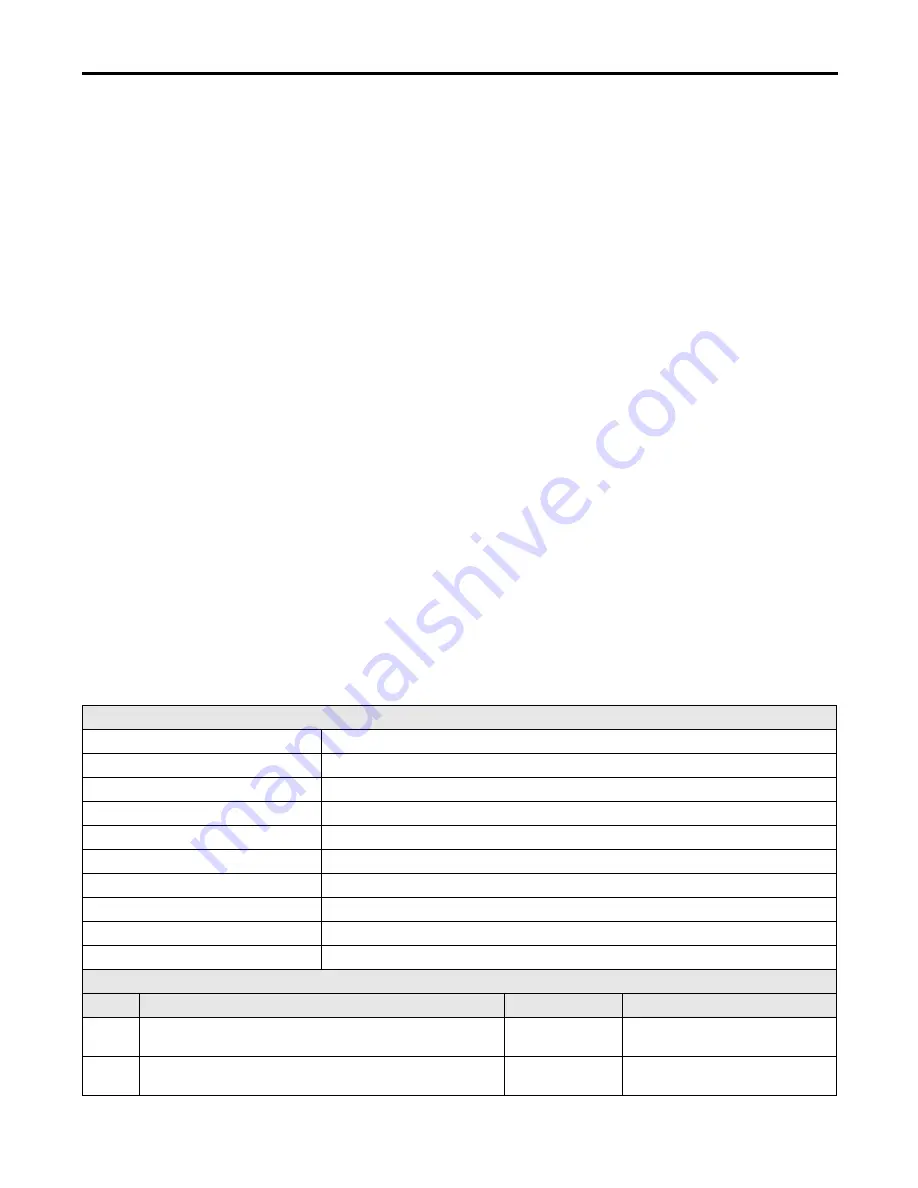

Verification and Validation Checklist

General Machinery Information

Machine Name/Model Number

Machine Serial Number

Customer Name

Test Date

Tester Name(s)

Schematic Drawing Number

Input Devices

440N-Z21SS2AN9

GuardMaster Dual-input Safety Relay

440R-D22R2

GuardMaster Multifunction-delay Expansion Module

440R-EM4R2D

Variable Frequency Drive

25B-B5PON104 (PowerFlex 525 drive) or 25C-V2P5N104 (PowerFlex 527 drive)

Safety Wiring and Relay Configuration

Test Step

Verification

Pass/Fail

Changes/Modifications

1

Confirm that all components' specifications are suitable for the application. Refer to

Basic Safety Principles and Well-tried Safety Principles from ISO 13849-2.

2

Visually inspect the safety relay circuit to confirm that it is wired as documented in the

schematics.