17-

274-

01 rev. 06

07/

18/

18

Thru-Hull:

Retractable with Valve

Shorty

™

Speed

&

Temperature Sensor

Models:

S300, ST300

Patent http://www.airmar.com/patent.html

Pretest

Connect the sensor to the instrument and spin the paddlewheel.

Check for a speed reading (and the approximate air temperature if

applicable). If there is no reading(s), check all the connections

and repeat the test. If there is still no reading(s) or it is inaccurate,

return the product to the place of purchase.

Applications

• Recommended for fiberglass or metal hull only

Never install a plastic housing in a wood hull, since swelling of

the wood can possibly fracture the plastic.

• Low profile P371 recommended for cruising sailboats or planing

hull powerboats

• Flush P398 recommended for racing sailboats or high-speed

powerboats

• Minimum space required above the installed sensor: 153mm (6")

• Accommodates hull thickness:

Minimum 6mm

(1/4")

Maximum 25mm

(1")

Tools & Materials

Safety glasses

Dust mask

Ear protection

Water based anti-fouling paint (

mandatory in salt water

)

Electric drill with minimum 10mm (3/8") chuck capacity

Drill bit

3mm

or

1/8"

Hole saw

51mm

or

2"

Countersink tool (installing P398 flush housing)

Sandpaper

Mild household detergent

or

weak solvent (such as alcohol)

File (installation in a metal hull)

Marine sealant (suitable for below waterline)

Additional washer [aluminum hull less than 6mm (1/4") thick]

Grommet(s) (some installations)

Cable ties

Installation in a cored fiberglass hull (page 3):

Hole saw for hull interior

60mm

or

2-3/8"

Fiberglass cloth and resin

or

Cylinder, wax, tape, and casting epoxy

Mounting Location

CAUTION

: Do not mount the sensor in line with or near water

intake or discharge openings; or behind strakes, fittings or hull

irregularities that may disturb the water flow.

CAUTION

: Do not mount the speed sensor directly ahead of a

depth transducer, since turbulence generated by the

paddlewheel’s rotation will adversely affect the transducer’s

performance, especially at high speeds. Mount side by side.

Turbulence-free water must flow under the paddlewheel at all

boat speeds. Choose an accessible spot inside the vessel. Allow

a minimum of 153mm (6") of headroom for the height of the

housing, tightening the nuts, and removing the insert.

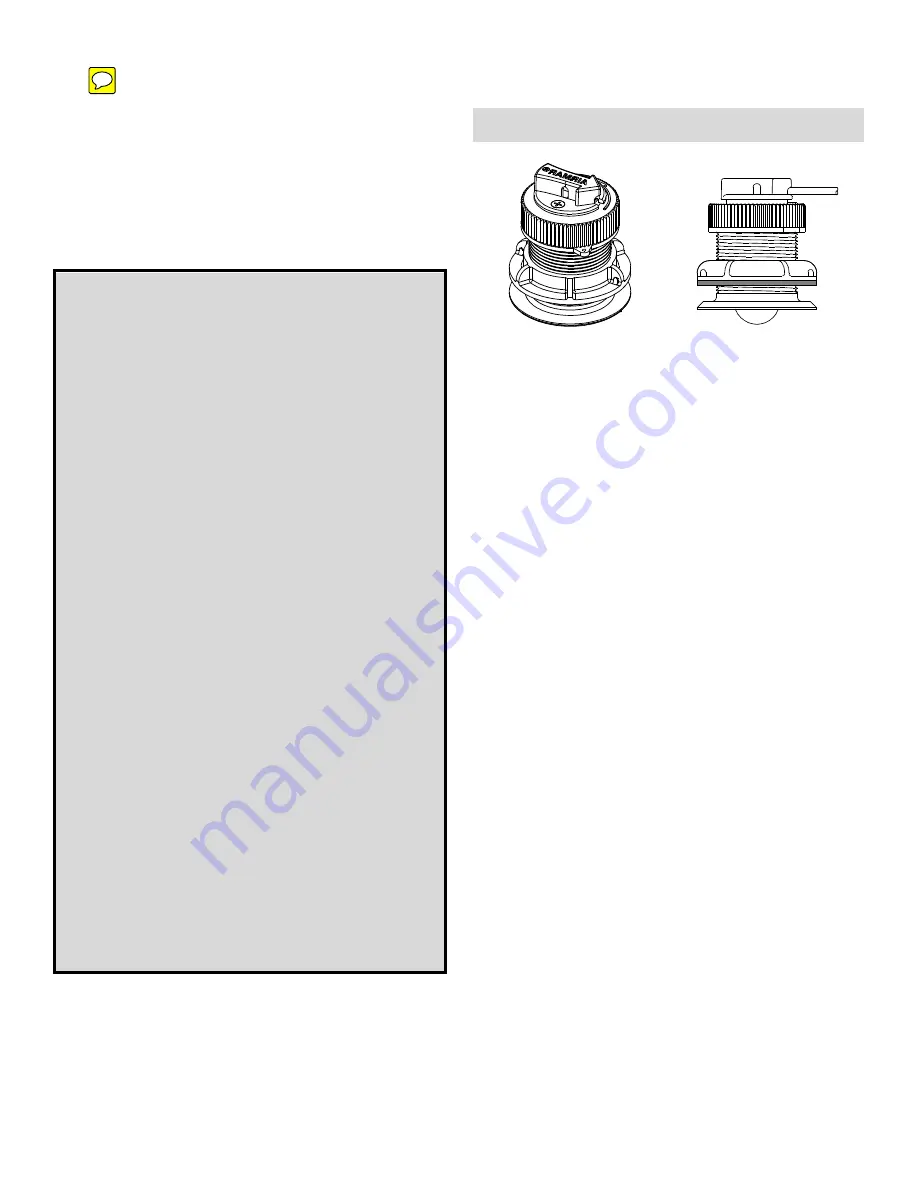

low-profile

flush

Record the information found on the cable tag for future reference.

Part No.:___________________Date___________

Follow the precautions below for optimal

product performance and to reduce the risk of

property damage, personal injury, and/or death.

WARNING

: Always wear safety glasses, a dust mask,

and ear protection when installing.

WARNING

:

The valve is not a watertight seal!

Always use the insert or the blanking plug secured

with the safety wire for a watertight seal.

WARNING

: The O-rings must be intact and well

lubricated to make a watertight seal.

WARNING

:

Always attach the safety wire to prevent

the sensor insert or blanking plug from backing out in

the unlikely event that the cap nut fails or is screwed

on incorrectly.

WARNING

: Immediately check for leaks when the boat

is placed in the water. Do not leave the boat unchecked

for more than three hours. Even a small leak may allow

considerable water to accumulate.

CAUTION

: Never pull, carry, or hold the sensor by its

cable; this may sever internal connections.

CAUTION

: Never use a fairing with a plastic housing;

the protruding sensor would be vulnerable to damage

from impact.

CAUTION

: Never use solvents. Cleaners, fuel, sealant,

paint, and other products may contain solvents that can

damage plastic parts.

IMPORTANT

:

Please read the instructions completely

before proceeding with the installation. These

instructions supersede any other instructions in your

instrument manual if they differ.

OWNER’S GUIDE & INSTALLATION INSTRUCTIONS

P371

P398