8

HOW TO USE YOUR SPREADER

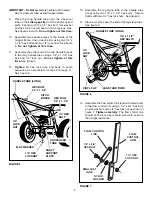

SETTING THE FLOW CONTROL

(Refer to figure 13 on page 7.)

1.

Loosen the nylon wing nut, set the adjustable stop to

the desired flow rate setting and retighten the wing

nut. The higher the setting number, the wider the

opening in the bottom of the hopper.

2.

Refer to the application chart on page 8 and to the

instructions on the fertilizer bag to select the proper

flow rate setting.

3.

Pull the flow control arm against the adjustable stop

for the on position and toward the hopper for the off

position.

OPERATION

USING YOUR SPREADER

We do not recommend the use of any powdered lawn

chemicals, due to difficulty in obtaining a satisfactory or

consistent broadcast pattern.

1.

Determine approximate square footage of area to be

covered and estimate amount of material required.

2.

Before filling the hopper make sure the flow control

arm is in the off position and the closure plate is shut.

3.

Break up any lumpy fertilizer as you fill the hopper.

4.

Set the adjustable stop with the flow control arm still in

the off position. Refer to the application chart on this

page and to the instructions on the fertilizer bag to

select the proper flow rate setting.

5.

The application chart is calculated for light to heavy

application at a walking speed of 3 mph, or 100 ft. in

23 seconds. A variation in speed will require an

adjustment of the flow rate to maintain the same

coverage. The faster you walk, the wider the broad-

cast width.

6.

Always start the spreader in motion before opening

the closure plate.

7.

Always shut the closure plate before turning or stop-

ping the spreader.

8.

If fertilizer is accidentally deposited too heavily in a

small area, soak the area thoroughly with a garden

hose or sprinkler to prevent burning of the lawn.

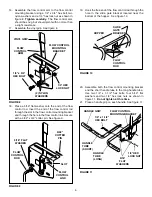

9.

To insure uniform coverage, make each pass so that

the broadcast pattern slightly overlaps the pattern

from the previous pass as shown in figure 14. The

approximate broadcast widths for different materials

are shown in the application chart on this page.

10. When broadcasting weed control fertilizers, make

sure the broadcast pattern does not hit evergreen

trees, flowers or shrubs.

FIGURE 14

APPLICATION DIAGRAM

OVERLAP

8’ to

10’

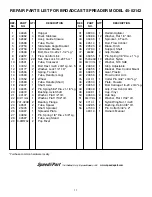

FERTILIZER

Powder

3 - 5

3' - 4'

Granular

3 - 5

8' - 10'

Pelleted

3 - 5

10' - 12'

Organic

6 - 8

6' - 8'

GRASS SEED

Fine

3 - 4

6' - 7'

Coarse

4 - 5

8' - 9'

ICE MELTER

6 - 8

10' - 12'

TYPE

SPREAD

MATERIAL

FLOW SETTING

WIDTH

APPLICATION CHART (SHIELD UP)

OPERATING SPEED

- 3 MPH. (100 ft. in 23 seconds)

IMPORTANT:

Application rates shown in the chart are

affected by humidity and by the moisture content of

the material (granular and pellet). Some minor set-

ting adjustments may be necessary to compensate

for this condition.