2

RULES FOR SAFE OPERATION

The following safety precautions are suggested. This

broadcast spreader is designed, engineered and tested

to offer reasonably safe and effective service, provided it

is operated in strict accordance with these instructions.

Failure to do so may result in personal injury. Always

observe the rules of safe operation.

1.

Do not allow anyone to operate the broadcast

spreader without proper instructions.

2.

Do not permit children to operate the broadcast

spreader.

3.

Wear eye and hand protection when handling and

when applying lawn or garden chemicals.

4.

Read the chemical label instructions and cautions

for handling and applying the chemicals purchased

for spreading.

5.

Keep all nuts, bolts and screws tight to be sure

equipment is in safe working condition.

6.

Follow maintenance and lubrication instructions as

outlined in this manual.

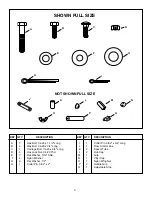

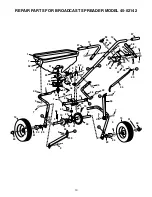

CARTON CONTENTS

LOOSE PARTS IN CARTON

1.

Handle Tube (long)

2.

Braces (2)

3.

Flow Control Mount Bracket

4.

Flow Control Arm

5.

Handle Tube (short)

6.

Flow Control Rod

7.

Leg Stand Tube

8.

Wheels (2)

9.

Hopper Assembly

Hardware Package (not shown)

2

6

5

1

7

9

3

4

8

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS. IT

MEANS -- ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED.