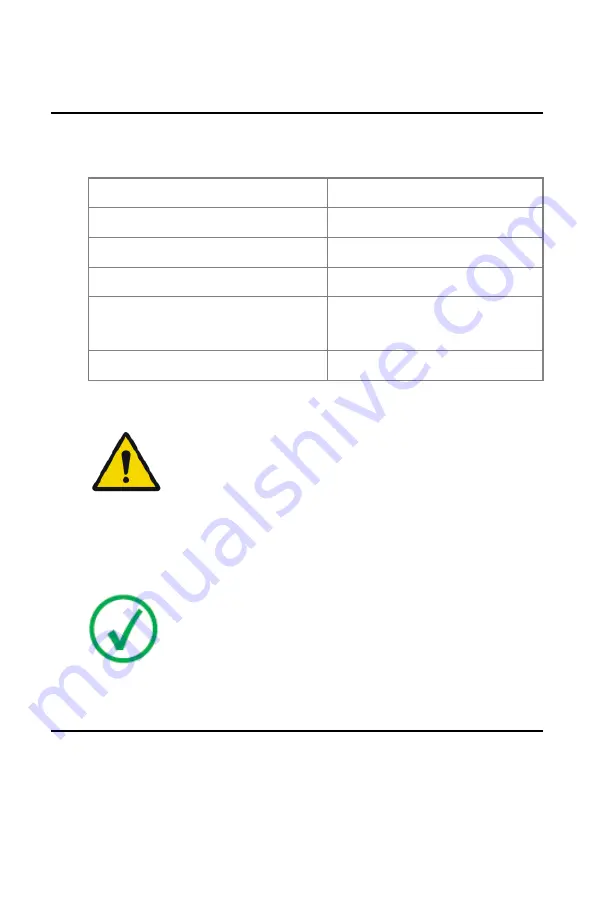

Preventive maintenance schedule

The printer is designed for trouble-free operation. Maintenance and cleaning

involve only some minor user tasks. Refer to the following pages for the

appropriate cleaning procedure.

Interval

What to do?

Ad hoc

‘Cleaning and disinfection’

Ad hoc

‘Print head cleaning’

Ad hoc

‘Cleaning the dust rollers’

Each 6 months

(or more if required).

‘Cleaning the cooling air flow holes’

When image quality tends to degrade.

‘Print head profile calibration’

Safety guidelines

WARNING:

To prevent damage to the printer while performing

maintenance, observe the following safety precautions:

• Do not lubricate the printer.

• Do not attempt to disassemble the printer.

• Do not touch the resistor line of the print head.

• Always switch off the printer and disconnect the power cord

from the outlet before carrying out any maintenance work.

Note

:

Film jam removal or cleaning the printer head can be done

without switching the power off.

Recurrent safety tests

The printer shall be tested according to IEC 62353* in a time interval of at

least 36 months or less if local regulations are different.

*Medical electrical equipment – Recurrent test and test after repair of medical

electrical equipment.

Drystar 5500, Drystar 5503 | Preventive maintenance and replacements |

111

2901J EN 20191018 0826