7.3 Connecting to the Network

515

7.3.2 Configuring Access to a Network Share

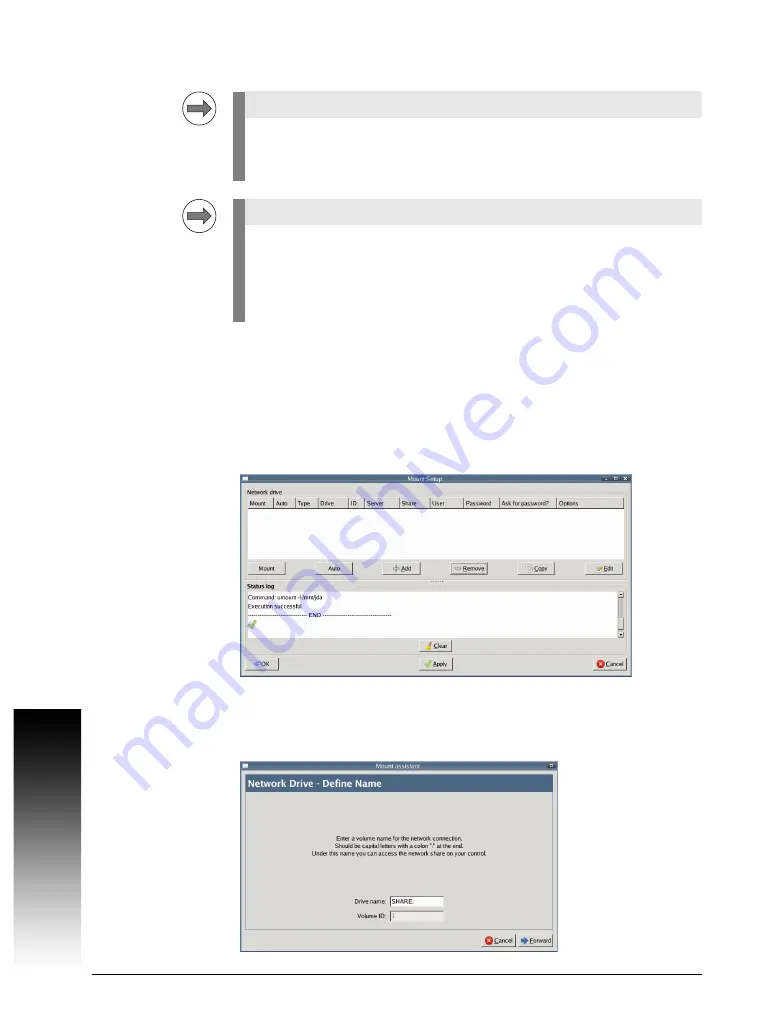

To access the required network share settings:

With the MILLPWR

G2

software running and the Emergency Stop pressed IN,

press the

Left Windows Flag

key on the USB keyboard, then use the arrow

keys to select

Settings

. Now select Shares from the list menu and press

Enter

.

The Network Settings window is now open.

Press the "+Add" key to open the "Mount assistant" window.

Enter the "Drive name" for the share. This is the name of the share as it will

appear in the control software screens. The name must end with a colon ":".

Note

The following procedure requires the entry of numbers and letters. So ple-

ase connect a USB keyboard to the MILLPWR

G2

before network sharecon-

figuration.

Note

You can only map to a root share folder of a server. For example, you can

map to \\server\share only, but can NOT map directly to \\server\share\fol-

der. You must also ensure that you have the proper credentials for the

username being used to access the share on the server (read, write,

delete).

Summary of Contents for MILLPWR G2

Page 1: ...Technical Manual ACU RITE MILLPWRG2 ...

Page 2: ......

Page 14: ...14 ACU RITE Technical Manual MILLPWRG2 ...

Page 40: ...40 ACU RITE Technical Manual MILLPWRG2 ...

Page 58: ...58 ACU RITE Technical Manual MILLPWRG2 3 10 3 USB Hub ...

Page 60: ...60 ACU RITE Technical Manual MILLPWRG2 TS 220 Adapter cable for TS 120 TS 220 ...

Page 61: ...3 10 Dimensions 61 SE 640 transmitter receiver unit ...

Page 62: ...62 ACU RITE Technical Manual MILLPWRG2 SE 540 transmitter receiver unit ...

Page 63: ...3 10 Dimensions 63 TS 440 TS 640 ...

Page 64: ...64 ACU RITE Technical Manual MILLPWRG2 ...

Page 392: ...392 ACU RITE Technical Manual MILLPWRG2 ...

Page 545: ......