Operation

29

6

Operation

6.1

Operating and Display Elements

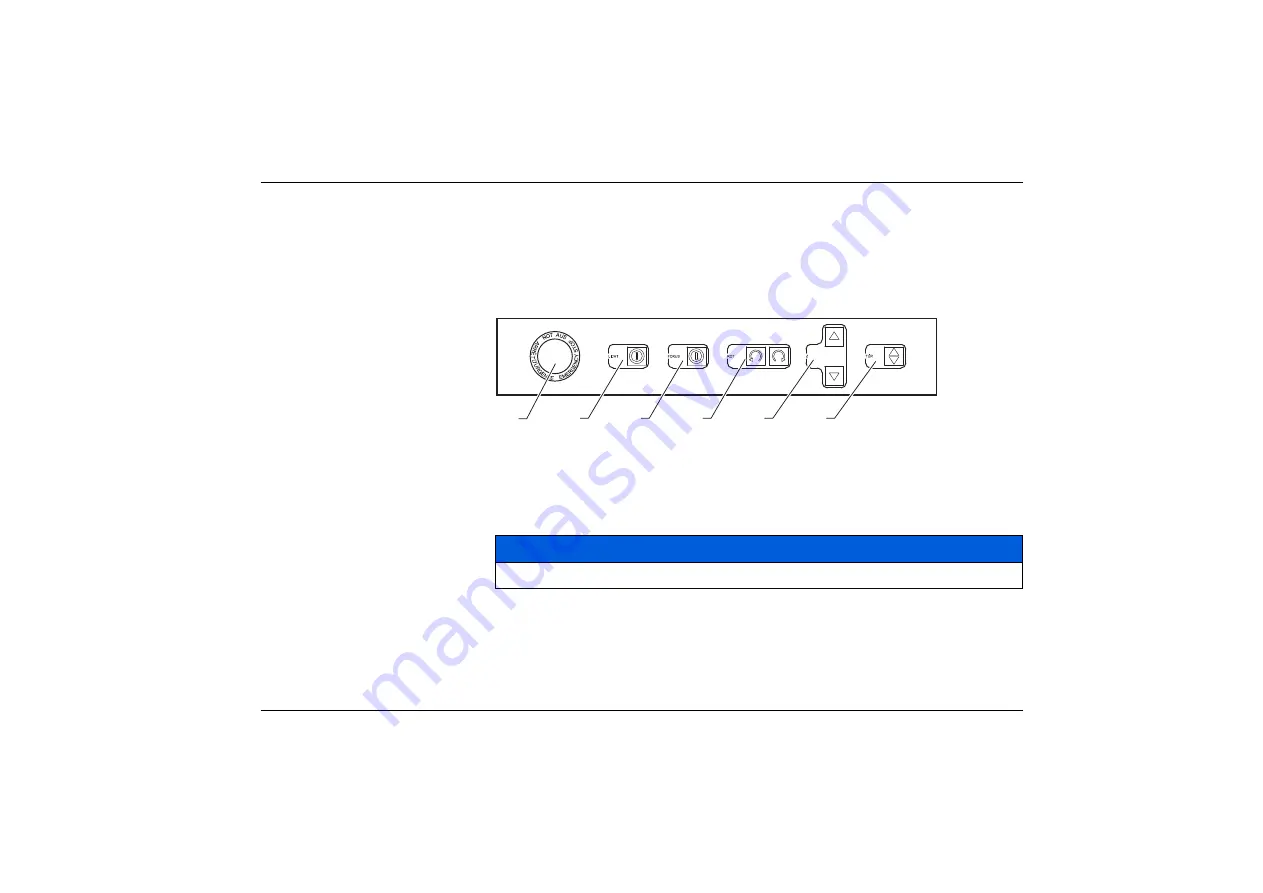

Control panel

In the setting-up mode, various functions may be controlled using the buttons on the

operator control panel.

The rotary module is set up with the

Rotation left/right

(4) buttons.

(1) Emergency stop button

(2) Light on/off

(3) Focus on/off

(4) Rotation left/right

(5) Z axis top/bottom

(6) Open/close door

NOTICE

Only the buttons enabled will be lit, depending on the current settings.

1

2

3

4

5

6

Summary of Contents for CLASSIC Fibre

Page 6: ...Table of Contents 6 ...

Page 37: ...Appendix 37 9 2 Drawing of the T Slot Plate A 360 A 2 5 14 5 25 20 12 5 8 1 346 375 ...

Page 39: ...Appendix 39 70 101 70 79 450 22 430 938 760 918 730 1159 Ø 50 Workstation CLASSIC Fibre XL ...

Page 41: ...Appendix 41 9 5 Illustration of the Rotary Module 100 92 ø 80 176 1 110 125 25 100 128 84 ...

Page 44: ...Appendix 44 ...

Page 49: ......