When replacing belts on multiple groove drives, all

belts should be changed to provide uniform drive

loading. Do not pry belts on or off the sheave. Loosen

belt tension until the belts can be removed by simply

lifting the belts off the sheaves. After replacing belts,

insure that slack in each belt is on the same side of

the drive. Belt dressing should never be used.

Do not install new belts on worn sheaves. If the

sheaves have grooves worn in them, they must be

replaced before new belts are installed.

The proper belt setting is the lowest tension at which

the belts will not slip under peak load operation. For

initial tensioning, set the belt deflection at 1/64-inch

for each inch of belt span (measured half-way

between sheave centers). For example, if the belt span

is 16 inches, the belt deflection should be 16/64-inch,

or 1/4-inch (using moderate thumb pressure at

mid-point of the drive). Check belt tension two times

during the first 24 hours of operation and periodically

thereafter.

Fan Motors

Motor maintenance is generally limited to cleaning

and lubrication. Cleaning should be limited to exterior

surfaces only. Removing dust and grease buildup

on the motor housing assists proper cooling. Never

wash-down the motor with high pressure spray.

Greasing of motors is only intended when fittings are

provided. Many fractional motors are permanently

lubricated for life and require no further lubrication.

Fan Wheel and Fasteners

Wheels require very little attention when moving clean

air. Occasionally oil and dust may accumulate on the

wheel causing imbalance. When this occurs, the wheel

and housing should be cleaned to assure smooth and

safe operation. Inspect fan impeller and housing for

fatigue, corrosion or wear.

Routinely check all fasteners, set screws and locking

collars on the fan, bearings, drive, motor base and

accessories for tightness. A proper maintenance

program will help preserve the performance and

reliability designed into the fan.

Fan Bearings

Most bearings are permanently lubricated and require

no further lubrication under normal use. Normal use

being considered -20°F to 120°F and in a relatively

clean environment. Some bearings are relubricatable

and will need to be re-greased depending on fan use.

Check your bearings for grease zerk fittings to find

out what type of bearing you have. If your fan is not

being operated under normal use, bearings should

be checked monthly for lubrication. Shaft bearings

are the most critical moving part of a fan. Therefore,

special attention should be given to keeping

the bearings clean and well-lubricated. Proper

lubrication provides for reduction in friction and

wear, transmission and dissipation of heat, extended

bearing life and prevention of rust.

In order for a lubricant to fulfill these tasks, the proper

grease applied at regular intervals is required. Refer to

the recommended bearing lubrication schedule:

If unusual conditions exist - temperatures below 32°F

or above 200°F, moisture or contaminants - more

frequent lubrication is required.

With the unit turning, add grease very slowly with

a manual grease gun until a slight bead of grease

appears at the seal.

Be careful not to unseat the seal by overlubricating

or using excessive pressure. A guide to the amount

of grease to be used is to fill 30% to 60% of available

space in the bearing and housing.

A high quality lithium grease conforming to NLGI

Grade 2 consistency, such as those listed below

should be used:

Mobil 532

Texaco Premium #2

B Shell Alvania #2

Mobilux #2

Texaco Multifak #2

Unirex 2

In addition to lubricating the bearings at specified

intervals, set screws in the bearing collars should be

checked for tightness. A bearing collar which has

loosened will cause premature failure of the fan shaft.

Fasteners attaching the bearings to the drive frame

should also be checked. See bearing lubrication

schedule.

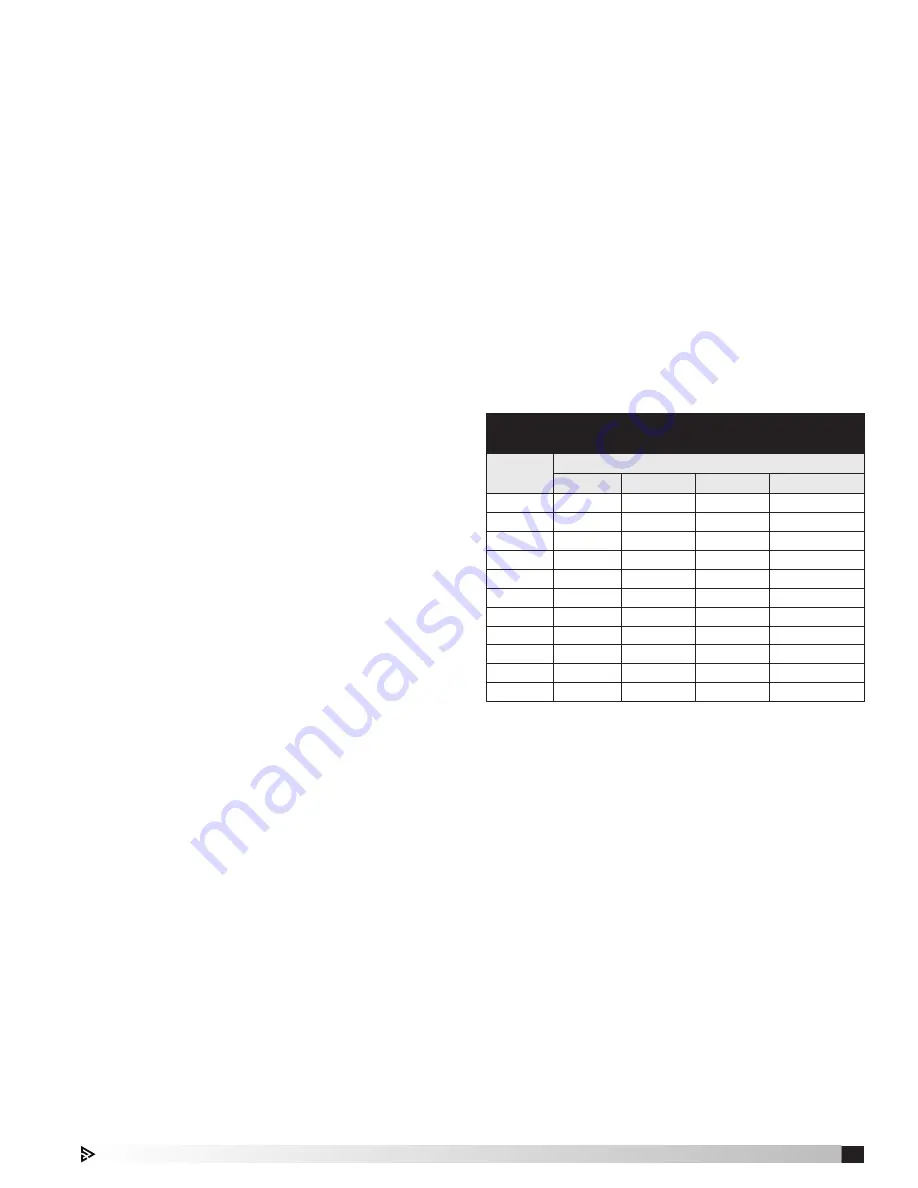

Plenum Fan Bearing Lubrication Schedule

(Relubrication Schedule in Months)

Fan

RPM

Shaft Diameter in Inches

1

⁄

2

to 1

1

1

⁄

8

to 1

1

⁄

2

1

5

⁄

8

to 1

7

⁄

8

1

15

⁄

16

to 2

3

⁄

16

To 250

6

6

6

6

500

6

6

6

5

750

6

5

4

3

1000

6

4

3

2

1250

5

3

2

1

1500

5

2

1

1

2000

5

1

1

.5

2500

4

.5

.5

.25

3000

4

.5

.25

.25

4000

3

.25

.25

.25

5000

2

.25

.25

.25

37

Model MPX Make-Up Air Unit

Model XMPX Make-Up Air Unit