20

User’s guide VUBB

|

1ZSC000562-AAL en

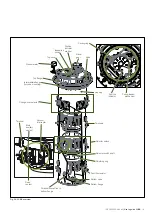

Fig. 31. The bevel gear can be turned 360°.

3.6 Mounting of external drive shafts

The external drive shafts consist of square tubes. They must

be connected to the spherical shaft ends of the bevel gear

and the motor-drive mechanism by means of two coupling

halves.

The bevel gear can be turned so that the horizontal shaft for

the motor-drive mechanism is in correctly positioned. See Fig.

31. The limit for turning depends on the arrangement of the

accessories, but the shaft can be at any angle.

CAUTION

Before mounting shafts and couplings, all parts must

be cleaned and greased to ensure correct function.

Let the parts of the shaft system that should be

dismantled before transporting the transformer

to the site keep their identification numbers

according to the packing list to simplify the

remounting of the shaft system on site.

The tubes around shafts and couplings are for

protection.

3.6.1 Mounting of horizontal drive shaft

1. Make sure that inclination of the shaft is less than 4°.

(4° = 70 mm for every 1000 mm of shaft length.)

Protective tubes with slotted ends must be used.

Make sure that the slots on the protective tubes are

facing downwards.

Removal and inspection of the couplings must be

possible when one of the tubes is pushed into the

other.

2. Fit two coupling halves on one end of the shaft. See

Fig. 32.

3. Fit six screws and washers in the holes on the coupling

halves. See Fig. 33.

Fig. 32. Fit two coupling halves on the square shaft.

Fig. 33. Fit screws and washers to the coupling halves.