44

• Perform comprehensive mechanical and electrical

functional tests. Observe the instructions on

setting.

• Ensure that the bolted joints at the contact

locations of the conductor bar system and the

earthing connections are tight.

Note:

Above mentioned work may only be performed by

the after-sales service personnel of ABB or ade-

quately qualified personnel.

8.3.3

Breaker pole

The breaker pole with the vacuum interrupter is

maintenance-free up to reaching the permissible

number of vacuum interrupter operating cycles in

accordance with section „Permissible number of

vacuum interrupter switching operations“.

The working life of the vacuum interrupter is

defined by the sum current limit corresponding to

the equipment data in individual cases in

accordance with section „Permissible number of

vacuum interrupter switching operations“:

• When the sum current limit is reached, the

complete breaker poles are to be replaced.

Note:

Dismantling and Replacement of the complete

breaker poles should only be carried out by

ABB after-sales service personnel or by specially

trained personnel, particularly as proper adjust-

ment is necessary.

For testing the vacuum without dismantling the

circuit-breaker you may use:

• Vaccuum tester VIDAR, from Programma

Electric GmbH, Bad Homberg v.d.H.

The following test values have to be set for

checking of the internal interrupter chamber

pressure with the VIDAR vacuum tester:

Rated voltage of

DC test voltage

the circuit-breaker

12 kV

40 kV

17.5 kV

40 kV

24 kV

60 kV

Testing must always be performed with the device

switched off:

• 12 to 24 kV: with rated contact distance

• 36 kV:

with additional provisions

(obtainment of information from

breaker manufacturer necessary)

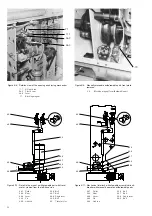

Procedure for vacuum interrupter testing for

stationary mounted switching devices:

• Isolate and secure the working area in

accordance with the Safety Regulations to

DIN VDE / IEC.

• Open the circuit-breaker.

• Earth all poles of the circuit-breaker on one side.

• Connect the earthed test lead of the the VIDAR

vacuum checker conductively to the station

earth.

• Connect the high voltage test lead of the VIDAR

vacuum checker with phase L1 of the unearthed

pole side and test the vacuum interrupter

chamber with the circuit-breaker contact gap

open. Repeat for phases L2 and L3.

Note:

Connected cables may lead to a “detective“

indication on the vacuum checker as a result of

their cable capacitance. In such cases, the cables

are not be removed.

8.4

Repair

8.4.1

VD4 circuit-breaker run-on block

In case of any irregularity in the area of the inner

control mechanism and of the charging function of

the stored-energy spring mechanism, the run-on

block disables the immediately subsequent

switching operation.

This is a protective measure to prevent damage to

the circuit-breaker

Release of the run-on block is described in

instruction manual BA 383/E.

8.4.2

Replacement of circuit-breaker parts and

accessories

Only remove and reassemble circuit-breaker parts

and accessories when the breaker has been switched

off and the working area is to be isolated and

secured against reclosing. The spring energy storage

mechanism must be discharged.

All supply voltage sources must be disconnected

and secured against reclosing during the removal

and installation work.

8.4.3

Touch up of surfaces

• Sheet steel parts, painted:

– Remove rust, e.g. with a wire brush.

– Grind off paint coat and degrease.

– Apply anti-rust primer and top coat.

– Use top coat paint in the standard colour

RAL 7035.

• Sheet steel parts, with zinc surface and

passivated functional parts:

– Remove white rust with a wire brush or

cleaning pad (e.g. Scotch-Brite white).

– Remove loosely adhering particles with a dry

cloth.

– Apply zinc spray or zinc dust primer.

• Functional parts, phosphated:

– Remove rust with a wire brush or cleaning pad

(e.g. Scotch-Brite white).