TB82 TRANSMITTER

PROBLEM AND ERROR CODES (TB82)

N - 23

PT.CHKS Incorrect or missing Pt 100

temperature sensor

checksum

Cycle transmitter power.

Remove transmitter from installed location and relocate to

noise-free environment. If problem does not appear, transmitter

needs new final location or additional shielding on transmitter

and/or wiring.

Contact ABB.

PT.F.CAL Out of range or missing

factory calibration for Pt 100

temperature sensor

Contact ABB for factory calibration procedure. Calibrate temper-

ature sensor for short-term usage until factory calibration can be

performed.

PZ.CHKS Incorrect or missing

reference impedance

measurement checksum

Cycle transmitter power.

Remove transmitter from installed location and relocate to

noise-free environment. If problem does not appear, transmitter

needs new final location or additional shielding on transmitter

and/or wiring.

Contact ABB.

PV.F.CAL Out of range or missing

factory calibration for PV

Contact ABB for factory calibration procedure. Calibrate sensor

for short-term usage until factory calibration can be performed.

ROM.EMI Unverifiable

EEPROM/ROM bus read

operation

Cycle transmitter power.

Contact ABB.

ROM.SUM Incorrect EPROM

checksum

Cycle transmitter power.

Contact ABB.

RZ.F.CAL Out of range or missing

factory calibration for

reference impedance

measurement

Contact ABB for factory calibration procedure. Reference imped-

ance diagnostic will not be operational until factory calibration is

performed. Disable diagnostics until factory calibration can be

performed.

SEE.EMI

Unverifiable SEEPROM bus

read operation

Cycle transmitter power.

Contact ABB.

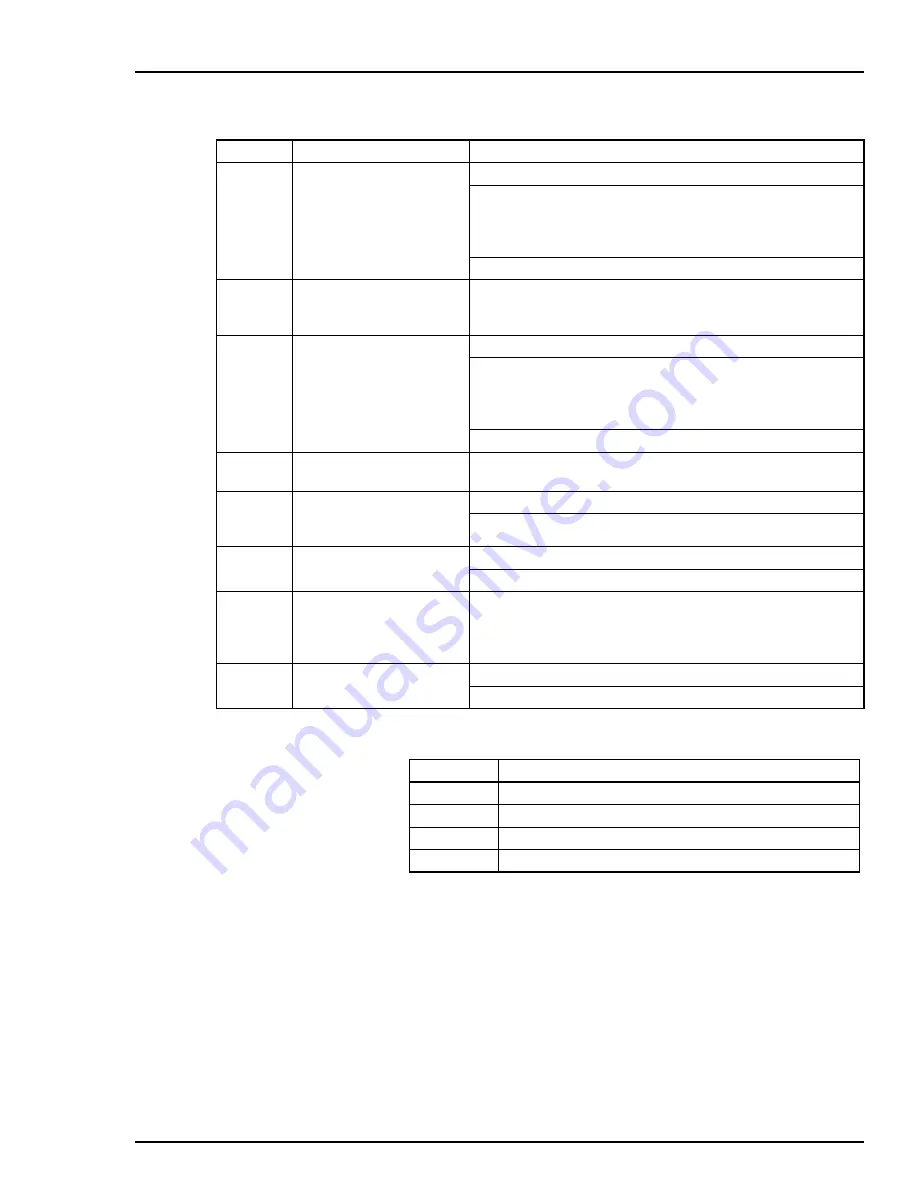

Table N-1. Problem Codes of TB82 Transmitter

(continued)

Code

Description

Corrective Action

Table N-2. Error Codes of the TB82 Transmitter

Code

Description

FC.PCB

4 wire conductivity board with pH/ORP/pION firmware.

HI.PV.AD

Overrange PV A/D.

LO.PV.AD

Underrange PV A/D.

TC.PCB

Toroidal conductivity board with PH/ORP/pION firmware.