Design and function

10

Thermal Mass Flowmeter FMT400-VTS, FMT400-VTCS (Sensyflow VT-S/VT-CS)

42/14-36 EN

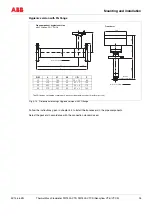

Pipe components in hygienic version

The pipe components in hygienic version are available for nominal pipe widths from DN 25 to DN 80, either with

FG flanges or threaded pipe connections S in accordance with DIN 11851.

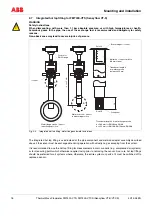

Fig. 3-2

Hygienic version FMT400-VTCS

The pipe components and weld-on adapters guarantee the defined installation of the transducer in the pipeline.

Moreover, they allow simple removal and installation of the transducer for inspection and/or cleaning.

By closing the pipe component with a blind flange, it is possible to use the measuring section even without

installed transducer.

The versions available as standard – depending on the respective nominal width and the desired adaptation –

are shown in chapter 10, “Technical Data”.

3.2

Transducer (detecting element)

The detecting element which is designed as a plug-in sensor contains, apart from the sensor unit, the completely

cast transmitter switching unit installed in the connection head. This is mainly composed of the passive part of

the differential temperature controller for the sensor elements, a memory for all parameter-related measuring

points, the connector for the LCS adapter and the computer for generating flow-specific data.

In addition, a flow-linearized analog signal of 0/4…20 mA (electrically isolated) is directly provided. No special

supply/evaluation device is required.

The transducer is flanged or screwed into pipe component as a plug-in sensor with a centering pin in a defined

manner.

See also chapter 10, “Technical Data”.

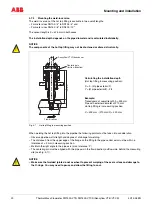

Transducer FMT400-VTCS

Pipe component FMT400-VTCS

Centering pin on outlet side

The figure shows process connections

with pipe fitting S acc. to DIN11851.

The transducer and the pipe component

are also available with FG flanges.

FG flanges on the pipe component are

always plain on both sides (without

groove).