Page 2–34

2101510 Rev. AG

2.16.1 Gas Types

The user can select from one of four sample conditioning modules for installations

whose gas samples do not meet the ideal clean and dry conditions. The following

definitions define what is meant by the condition of natural gas to be sampled.

•

Clean gas is defined as having no particles larger than one micron and no

more than one milligram of solids per cubic meter of gas.

•

Dry gas is defined as having no more than seven pounds of water per million

cubic feet of gas. Gas has less than 0.1 PPM of liquid at the coldest ambient

condition expected at the coldest point in the system. The liquid can be

water, oil, synthetic lubrication, glycol, condensed sample or any other non

vapor contaminate.

•

Stable gas is a vapor containing less than 0.1 PPM of liquid when vapor is

cooled to 18.3

°

F (10

°

C) below the coldest ambient temperature possible at

any point in the system.

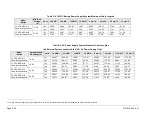

Figure 2-24 Available Sample Conditioning Modules

Table 2–10 Sample Conditioning Module Descriptions

Part Number

Description

2102024-001

Designed for sample point distances greater than 10’ (3 m) and less than 150’ (50 m) with

known particulate and liquid contamination. For stable gas samples containing pipe scale

and other solid contaminates and possibly minor amounts of liquid contamination. System

features:

•

Particulate/coalescing filter

•

Liquid/vapor separator

2102494-001

Designed for sample point distance greater than 50’ (15m) and less than 150’ (50m). The

sample gas is known to contain particulate and liquid contamination with a good

probability of line flooding in upset conditions, enough at times to overflow the coalescer

(a+ avenger) filter. It also has a Genie membrane for liquid rejection and a Genie liquid

shut off to be used when liquid carry over would harm the chromatograph if it was

introduced as a sample. This model contains a liquid shut off to protect the GC. The liquid

shut off resets itself when liquids are no longer present.

2102024-001

2102494-001

2104677-001