Page 2–22

2101510 Rev. AG

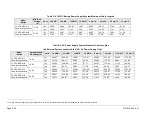

Table 2–6 Internal Volume of Commonly Used Sample Transport Tubing

Tube Outside Diameter

(in.)

Tube Wall Thickness (in.)

Volume per Foot (cc)

1/8

0.02

1

1/4

0.035

5

3/8

0.035

15

1/2

0.035

25

2.7.5

Gas Volume in Transit Tubing

Gases are compressible, and the volume of gas in transport tubing for standard

conditions (atmospheric pressure and 70

°

F [21.1

°

C]), is a function of gas pressure

and temperature within tubing.

Ideal gas equation:

nRT

PV

=

Where:

P

=

Pressure

V

=

Volume

T

=

Temperature

R

=

Universal Gas Constant

n

=

Number of moles in sample transport tubing.

“n” is used to calculate number of moles of gas sample contained in a certain

volume of sample transport tubing.

2.7.6

Mole

Mole is a fundamental unit that describes the number of chemical molecules. One

mole always represents one Avogadro’s number 6.02 x 1023 of molecules.

Number of moles can be determined by the calculation formula: n = PV/RT.

Because sample and transport tubing volume and temperature are usually

constant, the number of sample moles in transit is a function of pressure in sample

transport tubing. Reducing gas sample pressure reduces the mass of gas in

sample transport tubing. This is referred to as line peak. Once transport volume is

known for standard conditions, transport lag time can be determined.

2.7.7

Maintaining Phase

When designing sample transport tubing, phase of sample must be maintained.

Gases containing high concentrations of high boiling components can cause

problems when they condense on the inside of the transport tubing surface. To

prevent condensation from occurring, heat trace transport tubing uses electrical

power, stream or hot glycol. This prevents components from condensing on

transport tubing walls and prevents any water within the tubing from freezing and

blocking sample flow.