•

The system is in manual mode.

Note that LoadIdentify cannot be used for

tool0

.

Prerequisites for payloads

Before running the LoadIdentify service routine for a payload, make sure that:

•

The tool and payload are correctly mounted.

•

Axis 6 is close to horizontal.

•

The tool load is known (run LoadIdentify for the tool first).

•

The upper arm load is defined, if the payload mass is to be identified.

•

When using a moving TCP, the tool must be calibrated (TCP).

•

When using a stationary TCP, the corresponding work object must be

calibrated (user frame and object frame).

•

The axes 3, 5, and 6 are not close to their corresponding working range limits.

•

The speed is set to 100%.

•

The system is in manual mode.

Note that LoadIdentify cannot be used for

load0

.

Running LoadIdentify

To start the load identification service routine you must have an active program in

manual mode and the tool and payload that you want to identify must be defined

and active in the

Jogging

window.

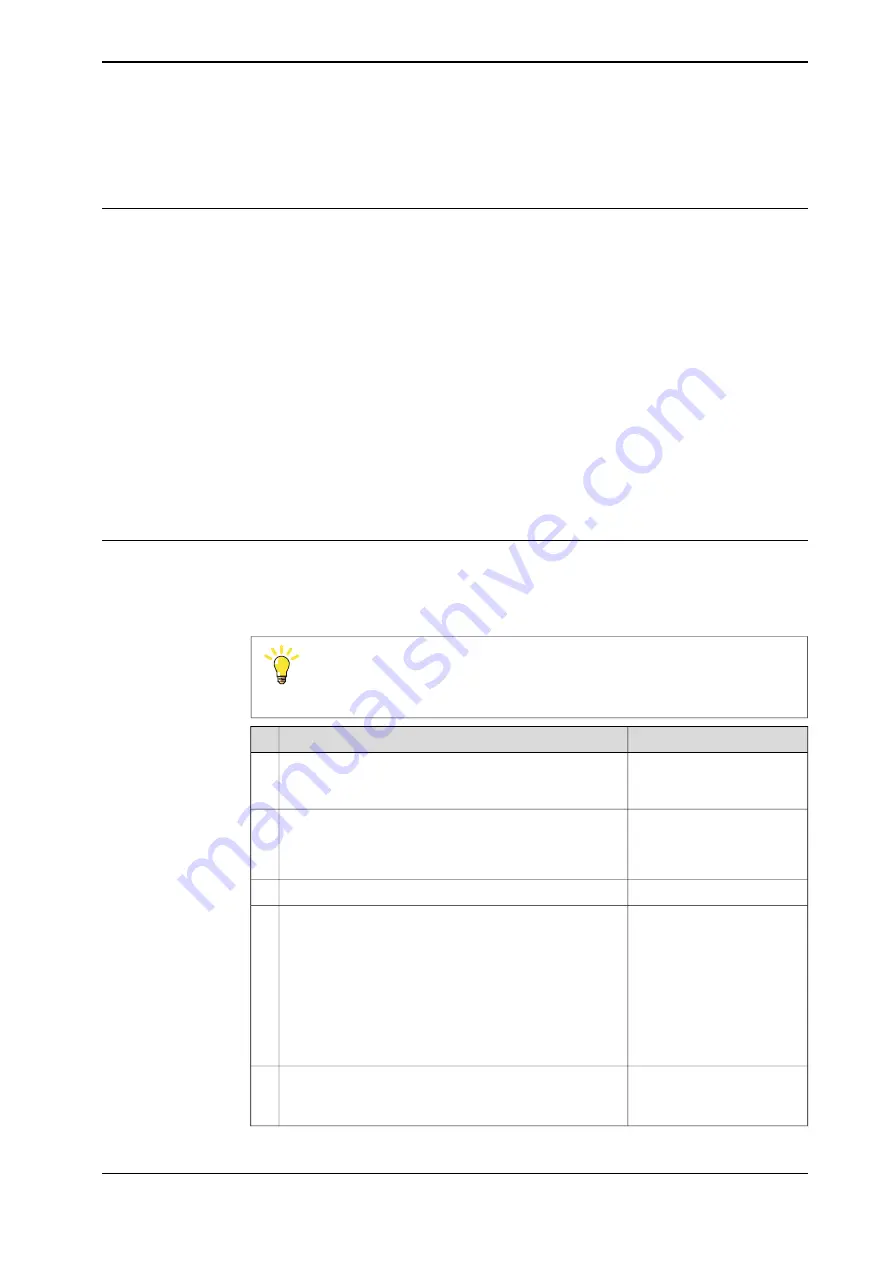

Tip

Always run load identification with cold motors (no warm-up).

Information

Action

How to start service routines

is described in

Start LoadIdentify from the

Program Editor

. Press the

three-position enabling device and then press the

Start

button on the FlexPendant.

1

Tap

Cancel

and then

Cancel

Call Rout

to quit the service

routine without loosing the

program pointer.

Tap

OK

to confirm that current path will be cleared and

that the program pointer will be lost.

2

Tap

Tool

or

Payload

.

3

If it is not correct, release the

three-position enabling

device and select the correct

tool/payload in the

Jogging

menu. Then return to Load-

Identify, press the three-pos-

ition enabling device, and

press Start. Tap

Retry

and

confirm that the new

tool/payload is correct.

Tap

OK

to confirm that the correct tool and/or payload

is active in the jogging menu and that the tool load/pay-

load is correctly mounted.

4

See

When identifying tool loads, confirm that the tool is active.

5

When identifying payloads, confirm that the payload’s

tool is active and calibrated.

Continues on next page

Operating manual - IRC5 with FlexPendant

227

3HAC050941-001 Revision: G

© Copyright 2018 ABB. All rights reserved.

5 Programming and testing

5.9.5 LoadIdentify, load identification service routine

Continued

Summary of Contents for IRC5 with FlexPendant

Page 1: ...ROBOTICS Operating manual IRC5 with FlexPendant ...

Page 14: ...This page is intentionally left blank ...

Page 120: ...This page is intentionally left blank ...

Page 146: ...This page is intentionally left blank ...

Page 240: ...This page is intentionally left blank ...

Page 286: ...This page is intentionally left blank ...

Page 294: ...This page is intentionally left blank ...

Page 298: ...This page is intentionally left blank ...

Page 304: ......

Page 305: ......