5.3.2 Handling of modules

Overview

This section details how to handle program modules. i.e.:

•

create a new module

•

load an existing module

•

save a module

•

rename a module

•

delete a module

Creating a new module

This section describes how to create a new module.

Action

On the

ABB

menu, tap

Program Editor

.

1

Tap

Modules

.

2

Tap

File

, then tap

New Module

.

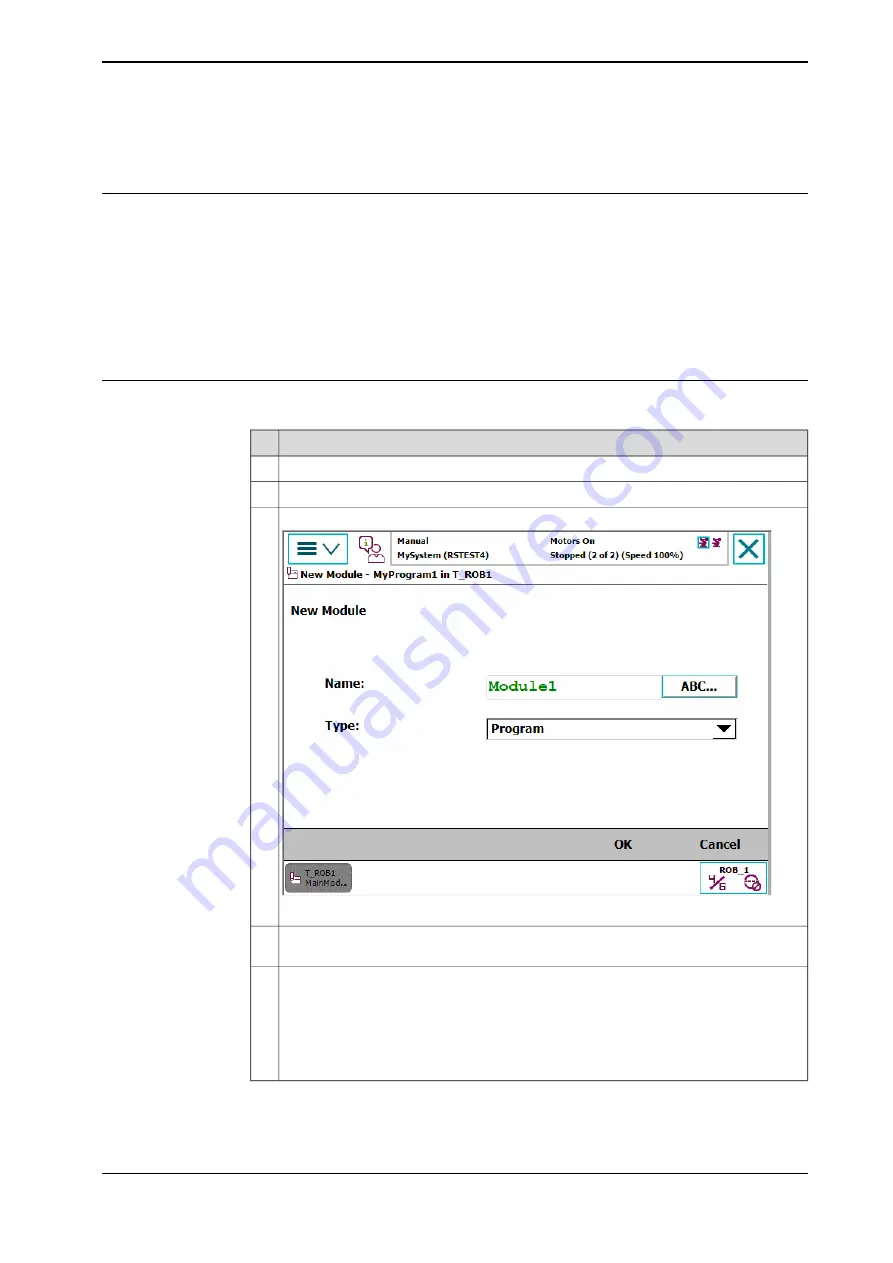

en0400000688

3

Tap

ABC...

and use the soft keyboard to enter the new module's name. Then tap

OK

to close the soft keyboard.

4

Select which type of module to be created:

•

Program

•

System

Then tap

OK

.

5

How to later switch between these types is detailed in section

Continues on next page

Operating manual - IRC5 with FlexPendant

153

3HAC050941-001 Revision: G

© Copyright 2018 ABB. All rights reserved.

5 Programming and testing

5.3.2 Handling of modules

Summary of Contents for IRC5 with FlexPendant

Page 1: ...ROBOTICS Operating manual IRC5 with FlexPendant ...

Page 14: ...This page is intentionally left blank ...

Page 120: ...This page is intentionally left blank ...

Page 146: ...This page is intentionally left blank ...

Page 240: ...This page is intentionally left blank ...

Page 286: ...This page is intentionally left blank ...

Page 294: ...This page is intentionally left blank ...

Page 298: ...This page is intentionally left blank ...

Page 304: ......

Page 305: ......