3 Repair activities, manipulator

3.1.1 Removal of cable harness

24

A

3HAC 16247-1

Section 3.1: Complete manipulator

3.1.1 Removal of cable harness

Location com-

plete cable har-

ness

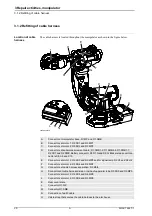

The cable harness is located throughout the manipulator as shown in the figure below.

xx0200000210

A

Connector at manipulator base, R1.MP and R1.SMB

B

Connectors at motor 1; R2.FB1 and R2.MP1

C

Connectors at motor 2; R2.FB2 and R2.MP2

D

Connectors at serial measurement board; R1.SMB1-3, R1.SMB4-6, R1.SMB1.7,

R2.FB7 and R2.SMB. Battery connector X3 R1.G and R2.G. Connectors at brake

release unit X8, X9 and X10.

E

Connectors at motor 3; R2.FB3 and R2.MP3 and for signal lamp R2.H1 and R2.H2

F

Connectors at motor 4; R2.FB4 and R2.MP4

G

Connectors at cable harness separation; R2.M5/6

H

Connectors at cable harness division, inside of upper arm tube; R3.FB5 and R3.MP5.

Connectors at motor 5; R4.FB5 and R4.MP5.

J

Connectors at motor 6; R3.FB6 and R3.MP6

K

Rear cover plate

L

Connector R1.MP

M

Connector R1.SMB

N

Connection of earth cable

O

Velcro strap that secures the cable harness to the arm house

A

B

C

D

E

F

G

H

J

K

O

L

M

N

Summary of Contents for IRB 6600 - 175/2.55

Page 2: ......

Page 6: ...Product Specification IRB 6600 2 Product Specification IRB 6600 M2000 ...

Page 82: ...Specification of Variants and Options 78 Product Specification IRB 6600 M2000 ...

Page 84: ...Accessories 80 Product Specification IRB 6600 M2000 ...

Page 116: ...Description 30 Product Specification S4Cplus M2000 BaseWare OS 4 0 ...

Page 136: ...Specification of Variants and Options 50 Product Specification S4Cplus M2000 BaseWare OS 4 0 ...

Page 140: ...Index 54 Product Specification S4Cplus M2000 BaseWare OS 4 0 ...

Page 141: ...Product Specification RobotWare Options 3HAC 9218 1 Rev 2 BaseWare OS 4 0 ...

Page 146: ...Introduction 4 Product Specification RobotWare Options for BaseWare OS 4 0 ...

Page 201: ...Installation Manual IRB 6600 6650 M2000A 3HAC 16245 1 Revision A ...

Page 218: ...1 Safety service 1 3 7 Work inside the manipulator s working range 16 A 3HAC 16245 1 ...

Page 237: ...4 On site Installation 3HAC 16245 1 A 35 Chapter 4 On site Installation ...

Page 277: ...5 Electrical connections 3HAC 16245 1 A 75 Chapter 5 Electrical connections ...

Page 376: ...9 System directory structure 9 0 5 Handling mass memory storage capacity 174 A 3HAC 16245 1 ...

Page 406: ...10 Calibration 10 5 5 Retrieving offset values 204 A 3HAC 16245 1 ...

Page 410: ......

Page 411: ...Repair Manual part 1 IRB 6600 6650 M2000A 3HAC 16247 1 Revision A ...

Page 416: ...Table of Contents iv 3HAC 16247 1 ...

Page 418: ...0 0 1 Overview 2 A 3HAC 16247 1 ...

Page 428: ...1 Safety service 1 3 7 Work inside the manipulator s working range 12 A 3HAC 16247 1 ...

Page 570: ...3 Repair activities manipulator 3 6 8 Refitting of gearbox axis 6 154 A 3HAC 16247 1 ...

Page 616: ...5 Appendix 1 Part Lists 5 1 15 Arm extension set 450 mm 3HAC 12311 5 200 A 3HAC 16247 1 ...

Page 618: ...6 Appendix 2 Foldouts 6 0 1 Introduction 202 A 3HAC 16247 1 ...

Page 620: ...6 Appendix 2 Foldouts 6 0 2 Base incl Frame 204 A 3HAC 16247 1 ...

Page 622: ...6 Appendix 2 Foldouts 6 0 3 Frame Lower arm 1 206 A 3HAC 16247 1 ...

Page 624: ...6 Appendix 2 Foldouts 6 0 4 Frame Lower arm 2 208 A 3HAC 16247 1 ...

Page 626: ...6 Appendix 2 Foldouts 6 0 5 Upper arm 210 A 3HAC 16247 1 ...

Page 628: ...6 Appendix 2 Foldouts 6 0 6 Wrist complete 212 A 3HAC 16247 1 ...

Page 630: ......

Page 631: ...Maintenance Manual IRB 6600 6650 M2000A 3HAC 16246 1 Revision A ...

Page 636: ...0 0 1 Overview 2 A 3HAC 16246 1 ...

Page 646: ...1 Safety service 1 3 7 Work inside the manipulator s working range 12 A 3HAC 16246 1 ...

Page 740: ...6 Maintenance activities controller cabinet 6 3 5 Cleaning Drain filter 106 A 3HAC 16246 1 ...

Page 742: ......

Page 743: ...Repair Manual part 2 Circuit Diagrams IRB 6600 6650 M2000A 3HAC 16247 1 Revision A ...

Page 746: ...0 0 1 Overview 2 A 3HAC 16247 1 ...

Page 748: ......

Page 749: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Contents 101 01 ...

Page 750: ......

Page 751: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Connection Point Location 102 01 ...

Page 752: ......

Page 753: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Legend 103 01 ...

Page 754: ......

Page 755: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Brake Release Unit 104 01 ...

Page 756: ......

Page 758: ......

Page 759: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Serial Measurement Board 105 01 ...

Page 760: ......

Page 761: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Axis 1 106 01 ...

Page 762: ......

Page 763: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Axis 2 107 01 ...

Page 764: ......

Page 765: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Axis 3 108 01 ...

Page 766: ......

Page 767: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Axis 4 109 01 ...

Page 768: ......

Page 769: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Axis 5 IRB 7600 110 01 ...

Page 770: ......

Page 771: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Axis 5 IRB 6600 110 1 01 ...

Page 772: ......

Page 773: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Axis 6 111 01 ...

Page 774: ......

Page 776: ......

Page 778: ......

Page 780: ......

Page 781: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Switches axis 1 113 01 ...

Page 782: ......

Page 783: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Switches Fan axis 2 114 01 ...

Page 784: ......

Page 785: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Switches Fan axis 3 115 01 ...

Page 786: ......

Page 787: ...Revision No of sheets sheet 20 Circuit Diagram 3HAC 13347 1 Weld connections 116 01 ...

Page 792: ...Circuit Diagram 3HAC 5582 2 Rev 03 Contents Page 4 Circuit Diagram S4Cplus ...

Page 793: ...Revision 04 No of sheets sheet 1 0 107 Circuit Diagram 3HAC 5582 2 1 General Information ...

Page 794: ......

Page 795: ...Revision 04 No of sheets sheet 1 1 91 Circuit Diagram 3HAC 5582 2 Block Diagram ...

Page 796: ......

Page 797: ...Revision 04 No of sheets sheet 1 2 91 Circuit Diagram 3HAC 5582 2 View of Control Cabinet ...

Page 798: ......

Page 799: ...Revision 04 No of sheets sheet 1 3 91 Circuit Diagram 3HAC 5582 2 View of Control Cabinet ...

Page 800: ......

Page 801: ...Revision 04 No of sheets sheet 1 4 91 Circuit Diagram 3HAC 5582 2 Designation ...

Page 802: ......

Page 803: ...Revision 04 No of sheets sheet 1 5 91 Circuit Diagram 3HAC 5582 2 Designation ...

Page 804: ......

Page 806: ......

Page 807: ...Revision 04 No of sheets sheet 2 1 107 Circuit Diagram 3HAC 5582 2 Mains Connection ...

Page 808: ......

Page 809: ...Revision 04 No of sheets sheet 2 2 107 Circuit Diagram 3HAC 5582 2 Transformer Unit 400 600V ...

Page 810: ......

Page 811: ...Revision 04 No of sheets sheet 2 3 107 Circuit Diagram 3HAC 5582 2 Transformer unit 200 440V ...

Page 812: ......

Page 813: ...Revision 04 No of sheets sheet 2 4 107 Circuit Diagram 3HAC 5582 2 Power Supply ...

Page 814: ......

Page 816: ......

Page 818: ......

Page 820: ......

Page 821: ...Revision 04 No of sheets sheet 3 1 91 Circuit Diagram 3HAC 5582 2 Block Diagram Computer Unit ...

Page 822: ......

Page 823: ...Revision 04 No of sheets sheet 3 2 91 Circuit Diagram 3HAC 5582 2 Cabling in Computer Unit ...

Page 824: ......

Page 826: ......

Page 827: ...Revision 04 No of sheets sheet 3 4 91 Circuit Diagram 3HAC 5582 2 Computer Cooling ...

Page 828: ......

Page 830: ......

Page 832: ......

Page 834: ......

Page 835: ...Revision 04 No of sheets sheet 3 8 91 Circuit Diagram 3HAC 5582 2 Base Connector Unit ...

Page 836: ......

Page 838: ......

Page 840: ......

Page 841: ...Revision 04 No of sheets sheet 4 1 107 Circuit Diagram 3HAC 5582 2 Emergency Stop ...

Page 842: ......

Page 844: ......

Page 846: ......

Page 848: ......

Page 850: ......

Page 851: ...Revision 04 No of sheets sheet 5 1 107 Circuit Diagram 3HAC 5582 2 Block Diagram ...

Page 852: ......

Page 853: ...Revision 04 No of sheets sheet 5 2 107 Circuit Diagram 3HAC 5582 2 Rectifier Fans and Bleeder ...

Page 854: ......

Page 856: ......

Page 858: ......

Page 859: ...Revision 04 No of sheets sheet 5 5 107 Circuit Diagram 3HAC 5582 2 Servo Drive Units IRB 140 ...

Page 860: ......

Page 861: ...Revision 04 No of sheets sheet 5 6 107 Circuit Diagram 3HAC 5582 2 Servo Drive Units IRB 340 ...

Page 862: ......

Page 864: ......

Page 866: ......

Page 868: ......

Page 870: ......

Page 871: ...Revision 04 No of sheets sheet 5 11 107 Circuit Diagram 3HAC 5582 2 Control Cable IRB 140 ...

Page 872: ......

Page 874: ......

Page 876: ......

Page 878: ......

Page 880: ......

Page 882: ......

Page 884: ......

Page 885: ...Revision 04 No of sheets sheet 6 0 107 Circuit Diagram 3HAC 5582 2 6 External Axes ...

Page 886: ......

Page 887: ...Revision 04 No of sheets sheet 107 6 1 Circuit Diagram 3HAC 5582 2 External Axes ...

Page 888: ......

Page 890: ......

Page 892: ......

Page 894: ......

Page 896: ......

Page 898: ......

Page 900: ......

Page 902: ......

Page 904: ......

Page 906: ......

Page 907: ...Revision 04 No of sheets sheet 107 6 11 Circuit Diagram 3HAC 5582 2 DDU Cable IRB 6600 7600 ...

Page 908: ......

Page 910: ......

Page 912: ......

Page 914: ......

Page 916: ......

Page 917: ...Revision 04 No of sheets sheet 107 7 1 Circuit Diagram 3HAC 5582 2 I O Unit Position ...

Page 918: ......

Page 920: ......

Page 922: ......

Page 924: ......

Page 926: ......

Page 928: ......

Page 929: ...Revision 04 No of sheets sheet 107 7 7 Circuit Diagram 3HAC 5582 2 Relay I O Unit Input 1 16 ...

Page 930: ......

Page 932: ......

Page 934: ......

Page 935: ...Revision 04 No of sheets sheet 107 7 10 Circuit Diagram 3HAC 5582 2 Analogue I O Unit ...

Page 936: ......

Page 938: ......

Page 939: ...Revision 04 No of sheets sheet 107 7 12 Circuit Diagram 3HAC 5582 2 Interbus S Slave ...

Page 940: ......

Page 941: ...Revision 04 No of sheets sheet 107 7 13 Circuit Diagram 3HAC 5582 2 Profibus DP Slave ...

Page 942: ......

Page 943: ...Revision 04 No of sheets sheet 107 7 14 Circuit Diagram 3HAC 5582 2 Encoder Unit ...

Page 944: ......

Page 945: ...Revision 04 No of sheets sheet 107 7 15 Circuit Diagram 3HAC 5582 2 Profibus DP Master Slave ...

Page 946: ......

Page 948: ......

Page 949: ...Revision 04 No of sheets sheet 8 0 107 Circuit Diagram 3HAC 5582 2 8 Other Options ...

Page 950: ......

Page 951: ...Revision 04 No of sheets sheet 107 8 1 Circuit Diagram 3HAC 5582 2 Floppy Disk ...

Page 952: ......

Page 953: ...Revision 04 No of sheets sheet 107 8 2 Circuit Diagram 3HAC 5582 2 Service Equipment Supply ...

Page 954: ......

Page 956: ......

Page 958: ......

Page 960: ......

Page 962: ......

Page 964: ......

Page 965: ...Revision 04 No of sheets sheet 107 8 8 Circuit Diagram 3HAC 5582 2 External Control Panel ...

Page 966: ......

Page 968: ......

Page 969: ...Revision 04 No of sheets sheet 107 8 10 Circuit Diagram 3HAC 5582 2 Time Relay ...

Page 970: ......

Page 972: ......

Page 974: ......

Page 975: ...Revision 04 No of sheets sheet 107 8 13 Circuit Diagram 3HAC 5582 2 LAN Ethernet connection ...

Page 976: ......

Page 978: ......

Page 980: ......

Page 982: ......

Page 984: ......

Page 986: ......

Page 988: ......

Page 989: ...Revision 04 No of sheets sheet 9 0 107 Circuit Diagram 3HAC 5582 2 9 External Axis Cabinet ...

Page 990: ......

Page 991: ...Revision 04 No of sheets sheet 107 9 1 Circuit Diagram 3HAC 5582 2 Block Diagram ...

Page 992: ......

Page 994: ......

Page 995: ...Revision 04 No of sheets sheet 107 9 3 Circuit Diagram 3HAC 5582 2 Designation ...

Page 996: ......

Page 997: ...Revision 04 No of sheets sheet 107 9 4 Circuit Diagram 3HAC 5582 2 Mains Connection ...

Page 998: ......

Page 999: ...Revision 04 No of sheets sheet 107 9 5 Circuit Diagram 3HAC 5582 2 Transformer Unit ...

Page 1000: ......

Page 1001: ...Revision 04 No of sheets sheet 107 9 6 Circuit Diagram 3HAC 5582 2 Power Supply I O Supply ...

Page 1002: ......

Page 1003: ...Revision 04 No of sheets sheet 107 9 7 Circuit Diagram 3HAC 5582 2 Power Unit ...

Page 1004: ......

Page 1005: ...Revision 04 No of sheets sheet 107 9 8 Circuit Diagram 3HAC 5582 2 Rectifier Fans and Bleeder ...

Page 1006: ......

Page 1008: ......

Page 1010: ......

Page 1012: ......

Page 1014: ......

Page 1016: ......

Page 1018: ......

Page 1019: ...Revision 04 No of sheets sheet 107 9 15 Circuit Diagram 3HAC 5582 2 Service Equipment Supply ...