This guide provides mechanical and electrical installation information for the

E530 EtherCAT servo drive. For detailed content, please refer to the E530-EC

Servo system user manual (3AXD50001018672 [EN])。

1. Safety instructions

This section contains the safety instructions that must be followed when

installing, operating and maintaining the servo drive. If ignored, it may result in

personal injury or death and damage to the servo drive, motor or drive

equipment. Please read this section carefully before operating the servo drive.

This section lists only the most important safety information for drive

installation, operation and maintenance, For detailed content, please refer to

chapter

Safety

in the E530-EC Servo system user manual (3AXD50001018672

[EN]).

The manual uses these warning symbols:

1.1 Unpacking

1.2 Installation safety instructions

1.3 Wiring safety instructions

1.4 Grounding safety instructions

1.5 Operation safety instructions

1.6 Maintenance safety instructions

2. Product overview

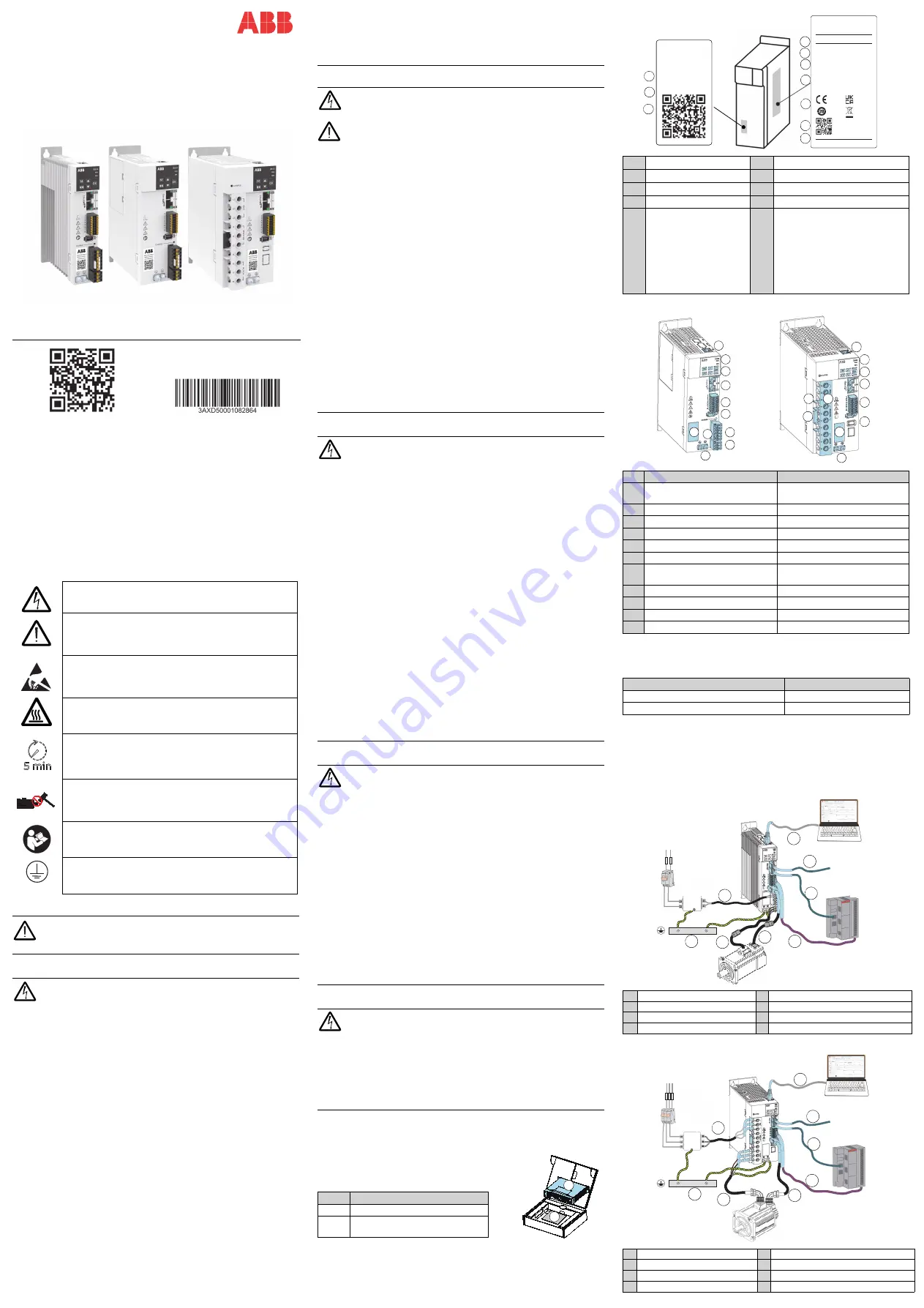

2.1 Drive components

As shown in the figure below, the package of the

drive contains the following components. Make sure

that all the items are present and there are no signs

of damage.

2.2 Drive labels

The drive has two labels:

•

Model information label

in front of the drive.

•

Type designation label

on the left side of the drive.

2.3 Drive interface

Note:

No need to distinguish zero and live wires for AC input ports L1 and L2 of

the drive (F2/F3).

Definition of drive port voltage level:

2.4 System structure

This section introduces the connection of the components in the servo drive

system, which helps the users quickly understand the E530 EtherCAT series

servo products. Different frame sizes have different power input and are used

with different types of motors. Taking F2 and F4 as examples, the typical

system connection diagram is shown below.

Frame size F2

Frame size F4

ABB Motion E-catalog

About this document

3AXD50001082864

Rev A EN 2023-12-01

©

2023 ABB All rights reserved.

Electricity warning

tells you about hazards from electricity

which can cause injury or death, or damage to the equipment.

General warning

tells you about conditions, other than those

caused by electricity, which can cause injury or death, or

damage to the equipment.

Electrostatic sensitive devices warning

tells you about the

risk of electrostatic discharge which can cause damage to

the equipment.

Surface high temperature warning

, tells you to pay attention

to the high temperature on the surface of the radiator, there

is a risk of scalding.

Remaining time warning

, displaying the remaining time for

capacitor discharge. After disconnecting the drive power

supply, be sure to wait for five minutes for the capacitor to

discharge. Otherwise, there is a risk of electric shock.

Motor machinery damage warning

tells you about the

dangerous operation like knocking which can damage the

motor.

Refering to the user manual warning

, tells you to read the

user manual and quick installation guide manual before

operating the device.

Grounding warning

, tells you about the protective grounding

(PE conductor terminal). Ensure that the equipment is

securely grounded.

Please check whether the drive type matches the product you ordered.

Make sure the specifications (rated power) of the servo drive and

motor are correctly matched. Ignoring this instruction could result in

personal injury or death or equipment damage.

Warning!

Do not connect the input power to the servo drive during

installation.

•

Move the servo drive carefully to avoid damage.

•

Use lifting equipment to lift the drive. Use the lifting lugs of the drive.

•

Do not tilt the drive. Overturning the drive may cause injury or damage.

•

Please keep the servo drive in the package before installation. After

unpacking, keep away from dust, debris and moisture.

•

Use required personal protective equipment: safety shoes with metal toe

caps, goggles, protective gloves and long sleeves, etc, as some parts have

sharp edges.

•

Do not install the servo drive in the environment of high temperature,

humidity, corrosive gas, flammable and explosive gas, metal dust, oil mist,

water vapor, etc.

•

Do not install the servo drive in a place with continuous vibration or physical

shock, strong electromagnetic interference, or sudden temperature change.

•

Do not fasten the servo drive by riveting or welding.

•

Before starting, vacuum clean the area around the drive to prevent the

cooling fan from sucking dust into the drive.

•

When installing, make sure that debris from drilling and grinding does not

enter the servo drive. Conductive debris inside the servo drive may cause

damage or malfunction of the device.

•

Install the mounting plate as vertical as possible and strong enough to

support the weight of the drive. Metal materials are recommended as the

material for mounting plate. The floor below the installation location should

be made of flame retardant material.

•

The installation site should be well ventilated or have adequate cooling

facilities to remove the heat emitted by the drive.

—

ABB Servo Product

E530-EC servo drive

Quick installation guide

•

Verify that all mounting frames are properly grounded and that contact

surfaces are free of paint.

•

This servo drive does not provide comprehensive mitigation for fire hazards.

It is intended to be installed inside a supplementary enclosure or in a

restricted-access area which provides appropriate protection against spread

of fire.

Warning!

Wiring to the drive must be done by a qualified electrical

engineer. Ignoring the following safety instructions may

cause

personal

injury or death and equipment damage.

Note!

Electrical design and installation must comply with local laws and

regulations. ABB is not responsible for installations that violate local

laws or regulations.

•

Dangerous voltage charges may remain in the drive even after a power

outage, so be sure to wait at least 5 minutes after a power outage to

measure to determine that the device is de-energized before performing any

wiring or inspections.

•

Avoid touching any other live parts in the workplace. Take special

precautions when working near exposed conductors.

•

Make sure that the servo system is safely grounded in accordance with local

regulations to ensure the reliability of the equipment.

•

Do not connect the servo drive to a voltage higher than that marked on the

model label, it can cause damage to internal components.

•

Do not solder exposed wires. Solder will shrink over time, potentially causing

loose connections. Use crimp connections whenever possible.

•

The AC power supply must be fused.

•

The control cable should have sufficient electrical safety distance from the

main circuit cable, or double or reinforced insulation isolation measures

should be provided between the control cable and main circuit cable.

•

After you disconnect power from the drive, always wait 5 minutes to let the

capacitors discharge before you continue.

•

Lock out and tag out after disconnection from power supply, to avoid any

misoperation.

•

E530 EtherCAT servo drive is suitable to be used with residual current

devices of Type B. Other measures for protection in case of direct or indirect

contact, such as separation from the environment by double or reinforced

insulation or isolation from the supply system by a transformer, can also be

applied.

Warning!

Please follow these instructions. Ignoring the following

safety instructions may cause personal injury, increase electromagnetic

interference, and lead to equipment failure. If you are not a qualified

electrical professional, do not perform grounding work.

•

Make sure that the servo drive, motor, and adjacent equipment are

grounded. This is a necessary measure to ensure personal safety. Proper

grounding can also reduce electromagnetic radiation and interference.

•

Make sure that the protective grounding (PE) conductor has sufficient

conductivity. Comply with local regulations.

•

Make sure that the size of the grounding wire meets the requirements of

safety regulations.

•

In a multi servo drive device, connect each one separately to the protective

grounding (PE) of the power supply.

•

When EMC emissions must be minimized, make a 360° grounding at the

cable entries in order to suppress electromagnetic disturbances. In

addition, connect the cable shields to protective earth (PE) in order to meet

safety regulations.

Note:

•

Power cable shields are suitable for equipment grounding conductors only

when adequately sized to meet safety regulations.

•

According to the requirements of standard EN 61800-5-1 (section 4.4.4.3.3),

due to the normal contact current of the servo drive being higher than 3.5

mA AC or 10 mA DC, a fixed protective grounding connection must be used:

- The cross-sectional area of the protective grounding conductor must be

at least 10 mm

2

copper wire or 16 mm

2

aluminum wire, or

- Automatically disconnect the power supply when the protective

grounding conductor is interrupted, or

- Replace with a backup protective grounding conductor with the same

cross-sectional area as the original protective grounding conductor.

•

Leakage current >3.5 mA AC.

Warning!

Before operation, adjust the drive parameters to match the

user-defined parameters of the mechanical system. Mismatched

parameters may cause damage to the servo drive, motor or mechanical

system.

•

Adjust the limit value (speed, current, etc.) of the servo drive, and make sure

that the motor and all driven equipment can run within the limit range.

•

Be careful with hot surfaces. During use, the surfaces of servo system

components (such as reactors or braking resistors) can become very hot and

remain hot for a period of time after the power is disconnected. Braking

resistors may generate enough heat to ignite flammable materials. To avoid

fire hazard, keep all flammable materials and flammable substances away

from the braking resistor.

•

Make sure that the safety circuits (eg emergency stop) connected to the

servo drive are verified.

•

The servo drive is allowed to power on up to 5 times every 10 minutes. Too

frequent power-ups can damage the DC capacitor charging circuit.

•

Before using the automatic fault reset or automatic restart function of the

servo drive, make sure that no dangerous situation occurs. After a fault or

power interruption, the servo drive automatically resets and continues to run

through these functions. If these functions are used, they must be clearly

marked on the equipment as specified in IEC/EN 61800-5-1, clause 6.5.3, eg

"This equipment will start up automatically".

Warning!

Maintenance and inspection of the drive should only be

performed by a qualified electrical engineer. Do not touch any internal

or external parts of the servo drive and motor, as doing so may result in

electric shock.

•

The fan and other components of the servo drive are replaced and

maintained by ABB or an authorized service center, Users are not allowed to

disassemble them.

•

Servo drives are not field repairable. Do not repair a malfunctioning servo

drive. If the servo drive fails, please contact your local ABB office or

authorized service center.

No.

Description

1

Servo drive

2

E530 EtherCAT variant servo drive

quick installation guide(ZH & EN)

ABB

1

2

1

Drive type

6

QR code (Production serial number)

2

Manufacturer information

7

Drive type

3

Degree of protection

8

Serial number

4

Nominal ratings

9

QR code (ABB servo web site)

5

Certification markings

10

S/N: Serial number of format

MYYWWXXXXX, where

M: Manufacturer designation

YY: Year of manufacture: 20, 21, 22,

…for year 2020, 2021, 2022…

WW: Week of manufacture: 01,02,03,

…for week 1, week 2, week 3...

XXXXX: Running item number that

starts each week from 00001.

No.

F2,F3

F4

1

Commissioning software

connection port (RJ 45)

Commissioning software

connection port (RJ 45)

2

Five digit seven segment LED

Five digit seven segment LED

3

Display operation buttons

Display operation buttons

4

EtherCAT communication interface EtherCAT communication interface

5

Control signal connector

Control signal connector

6

Encoder connector

Encoder connector

7

Input power and brake resistor

connection terminals

Input power, motor power and

brake resistor connection terminals

8

Motor power connection terminals Model information label

9

Model information label

Short-circuit connector

10 Short-circuit connector

Baffe

11 Grounding screws

Grounding screws

Drive port

DVC level

CN1/CN2/CN3

DVC As

L1/L2/L3/P/C/R/U/V/W

DVC C

1

Power cable, 1-phase

5

Communication cable (RJ45)

2

Motor cables

6

System grounding busbar

3 Encoder cable (1394 connector) 7 EtherCAT communication cable input

4 Control cable (16-pin connector) 8 EtherCAT communication cable output

1 Power cable, 1-phase or 3-phase 5

Communication cable (RJ45)

2

Motor cables

6

System grounding busbar

3 Encoder cable (1394 connector) 7 EtherCAT communication cable input

4 Control cable (16-pin connector) 8 EtherCAT communication cable output

7

8

9

5

1

2

3

4

6

10

E530-EC0S-0KW4-1

220 VAC, 0.40 kW, EC

S/N W2

!

12345

ABB Beijing Drive Systems Co.,Ltd.

No.1, Block D, A-10 Jiuxianqiao Beilu,

Chaoyang District, Beijing, P.R. China

Made in China

S/N W222312345

Output

Input

3P 0~U1

U2

1P 200~240VAC

U1

2.90 A

I2

4.7 A

I1

0~500Hz

f2

50/60Hz

f1

0.40 kW

Pn

E530-EC0S-0KW4-1

5 kA

Icc

Natural cooling

C

HW

IP20 Open type

ABB Oy

1

3

4

5

6

7

8

9

1

2

3

4

5

6

7

9

10

F2、F3

F4

2

11

10

11

8

Externl PC

(Install Servo Composer)

PLC/controller

220V AC power

Breaker

Fuse

Filter

1

2

3

4

5

6

8

Connect to the

next drive or

PLC to form

redundant

connections

PE

7

External PC

(Install Servo Composer)

PLC/controller

220V AC power

Breaker

Fuse

1

2

3

4

5

6

7

Connect to

the next drive

or PLC to form

redundant

connections

PE

8

Filter