Initial status: The drive is in operation and the motor is at a standstill.

Step

Operation

1.

The user activates Prevention of unexpected start-up by switching off the POUS

switch [Sxx].

2.

The POUS safety relay [A65] trips and the relay switches off the Safe torque off

(STO) control signals on the drive control board [A41]. The STO cuts off the drive

control pulses preventing motor control and generation of torque.

3.

The aux. contact of safety relay [A65] energizes the indication lamp [P7x].

4.

The motor does not generate torque and remains at zero speed while the POUS is

active.

5.

Normal operation resumes after the user:

−

releases the POUS button [Sxx] to normal (up) position

−

resets the POUS circuit with the POUS reset button [S7x] (if installed; the user

must push the reset button for 0.1 to 3 seconds)

−

resets the drive (if the STO indication parameter 31.22 has been set so that a

fault is generated)

−

makes sure that the drive has received the start signal (depends on the

configuration, see the firmware manual).

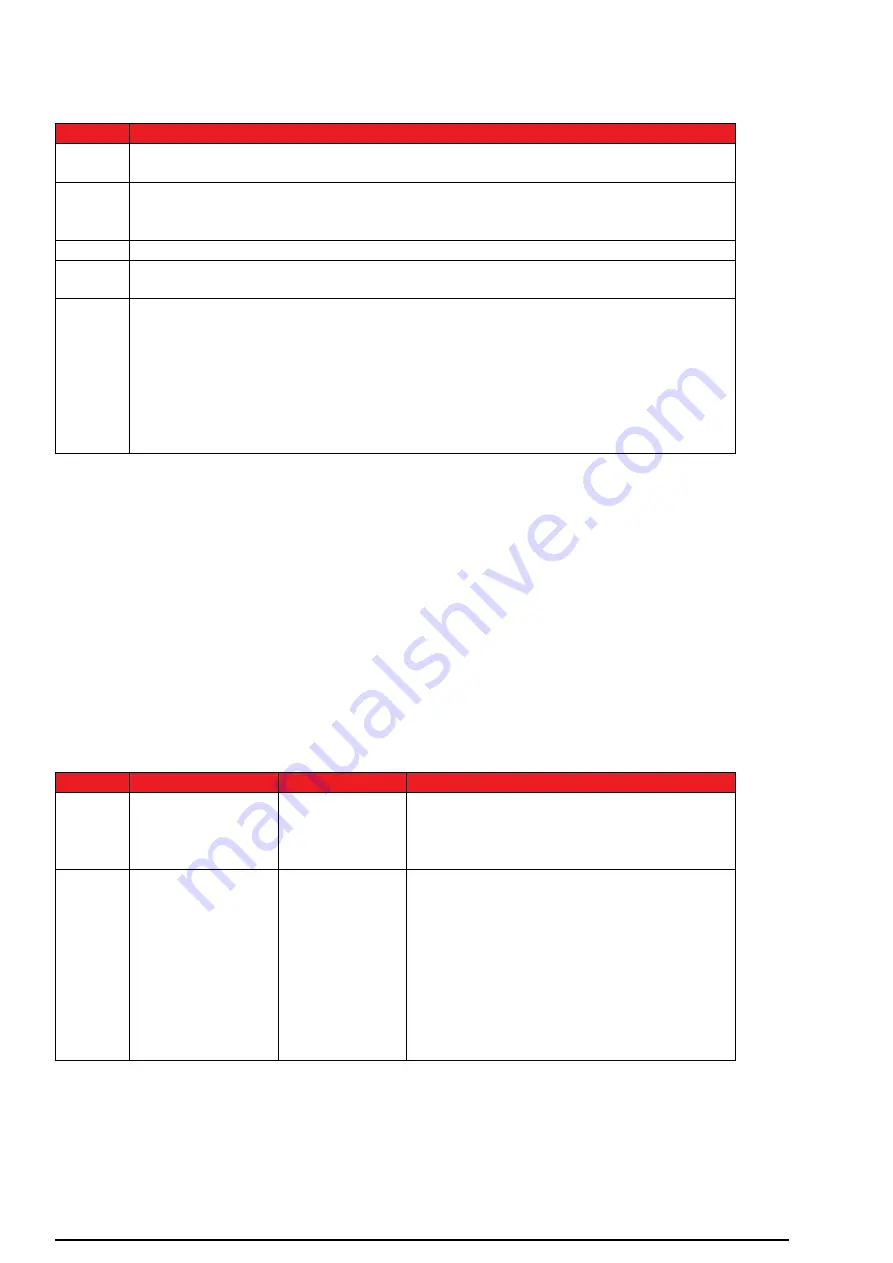

+Q957 Fault reaction function

Definition: A safety function requires a ‘fault reaction function’ that attempts to initiate a safe state if

the safety function's diagnostics detect a fault within the hardware/software that performs the safety

function.

The fault reaction function of the POUS safety relay [A65] trips if it detects a failure (short circuit

between signals, open circuits, redundancy fault) in the safety circuit. The fault reaction function shifts

the drive immediately into the safe state by activating the STO function. The STO function is active until

the fault is repaired. The POUS indication lamp is on until the fault is repaired.

The STO function has its own internal fault diagnostics and fault reaction function.

Parameter settings

This table lists the drive parameters settings for the +Q957 option. For more information, see the

firmware manual.

No.

Name

Value

Description

10.24

RO1 source

P.31.98b11

Selects a drive signal to be connected to

relay output RO1. In this case, the RO1 is

energized if the Drive is in STO state and no

STO related fault is active.

31.22

STO indication

run / stop

Fault /

Warning

Selects which indications are given when

one or both Safe torque off (STO) signals

are switched off or lost, depending on

whether the drive is Running / Stopped,

when they occur. When a fault occurs in the

drive, the mains contactor AC-B or DC-B is

opened by the XSMC-MC relay.

Fault/Warning is the recommended setting.

Use Warning / Warning if E-Stop, stop

category 0 (+Q951 or +Q563) is used.