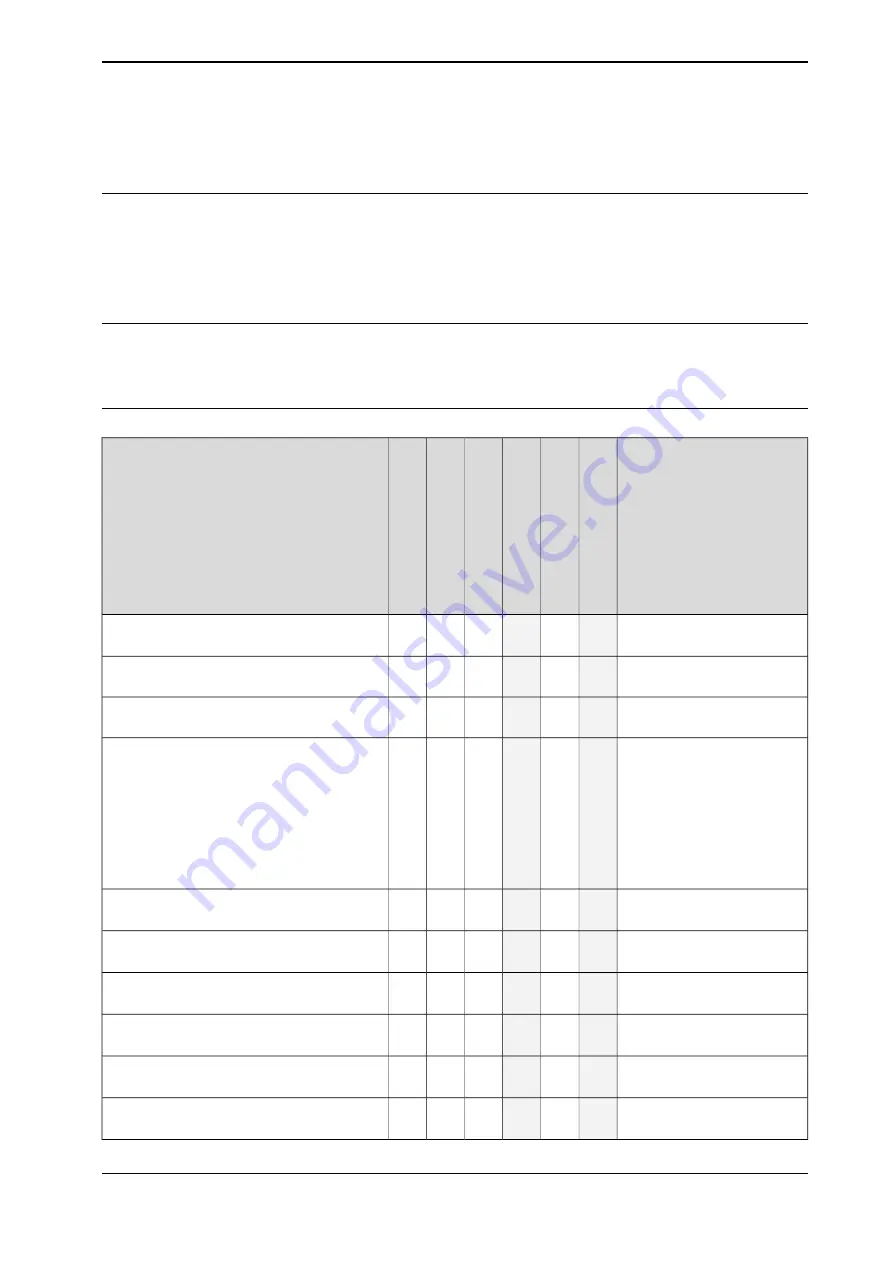

4.2.2 Maintenance schedule

Scheduled and non-predictable maintenance

The robot must be maintained regularly to ensure proper function. The maintenance

activities and intervals are specified in the table below.

Non-predictable situations also give rise to inspections of the robot. Any damages

must be attended to immediately!

Life of each component

The inspection intervals

do not

specify the life of each component. Values for these

are specified in the section

Expected component life on page 169

Maintenance schedule

Reference

Every

30,000

hours

ii

Every

24,000

hours

Every

12,000

hours

Every

36

months

Every

12

months

Regularly

i

Maintenance activities

x

Cleaning the robot

Check for abnormal wear or

contamination.

x

Inspecting the robot

Check for damages, defective

or lack of effectiveness.

x

Inspecting the laser scanners

Inspect the oil level of axis 2

in the actual gearbox if there

is a suspected leakage, after

an oil change or a

maintenance or repair activity

where draining and filling oil is

required.

See

Inspecting the oil level in gearboxes

x

Inspecting the information labels

x

iii

Inspecting the robot harness

x

Inspecting the mechanical stop

x

Inspecting the timing belt

x

iv

Lubricating the robot harness

x

v

Replacing the SMB battery pack

Continues on next page

Product manual - CRB 1300

167

3HAC083111-001 Revision: B

© Copyright 2022-2023 ABB. All rights reserved.

4 Maintenance

4.2.2 Maintenance schedule

Summary of Contents for CRB 1300

Page 1: ...ROBOTICS Product manual CRB 1300 ...

Page 50: ...This page is intentionally left blank ...

Page 662: ...This page is intentionally left blank ...

Page 690: ...This page is intentionally left blank ...

Page 704: ...This page is intentionally left blank ...

Page 720: ...This page is intentionally left blank ...

Page 725: ......