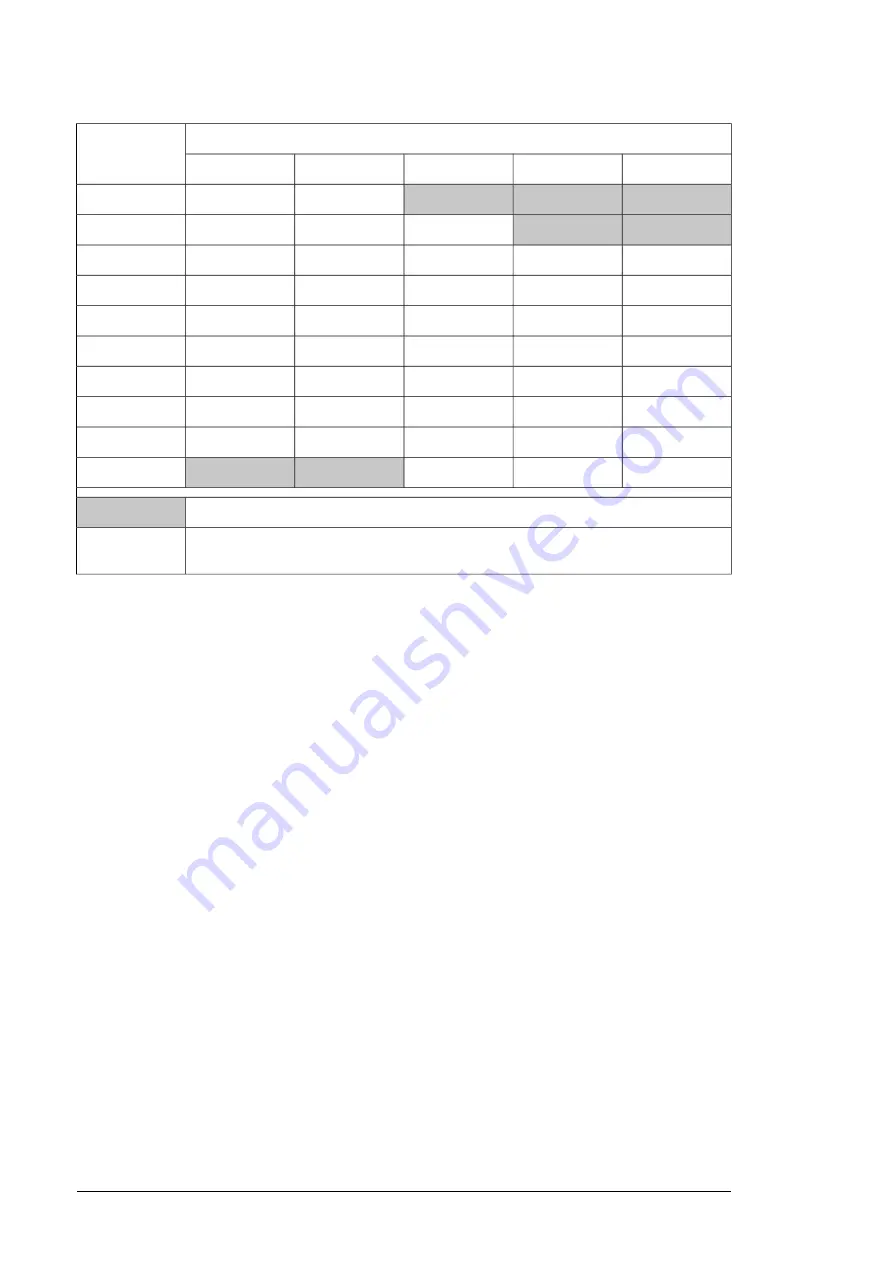

Min. T

coolant

(°C)

T

air

(°C)

RH = 40%

RH = 50%

RH = 65%

RH = 80%

RH = 95%

-3.0

-0.1

3.7

6.7

9.2

10

1.5

4.6

8.4

11.5

14.2

15

6.0

9.4

13.2

16.5

19.2

20

10.5

13.8

17.9

21.4

24.1

25

15.0

18.4

22.7

26.2

29.1

30

19.4

23.0

27.4

31.1

34.1

35

23.8

27.6

32.2

35.9

39.0

40

28.2

32.1

36.8

40.8

44.0

45

32.8

36.7

41.6

45.6

49.0

50

37.1

42.2

46.3

50.4

53.9

55

= Not allowed as standard but the coolant temperature must be 0 °C (32 °F) or above.

At an air temperature of 45 °C and relative humidity of 65% the coolant temperature may

not be below +36.8 °C

Example:

Maximum temperature rise:

Depends on heat losses and mass flow. Typically 10 °C (18

°F) with nominal losses and flow.

■

Pressure limits

Base pressure:

100 … 150 kPa (recommended); 200 kPa (maximum). “Base pressure”

denotes the pressure of the system compared with the atmospheric pressure when the

cooling circuit is filled with coolant.

Air counterpressure in the expansion tank:

40 kPa

Design pressure (PS):

600 kPa

Nominal pressure difference

(between main in/out lines): 120 kPa with 25/75% (volume)

coolant solution, 150 kPa with 50/50% (volume) coolant solution. This has to be taken into

account when dimensioning the liquid cooling circuit.

Maximum pressure difference

(between main in/out lines): 200 kPa

■

Coolant flow rate limits

The maximum coolant flow rate for all drive equipment is 1.3 × nominal. See the technical

data chapter for nominal values.

■

Cooling circuit materials

Materials used in the internal cooling circuit are listed below. These are also the only materials

that can be used in the external cooling circuit.

•

stainless steel AISI 316L (UNS 31603)

•

heavy gauge aluminum

•

plastic materials such as PA, PEX and PTFE

Note:

PVC hoses are not suitable for use with antifreeze.

178 Internal cooling circuit

Summary of Contents for ACS880-204LC

Page 1: ... ABB INDUSTRIAL DRIVES ACS880 204LC IGBT supply modules Hardware manual ...

Page 2: ......

Page 4: ......

Page 16: ...16 ...

Page 32: ...32 ...

Page 39: ...Overview of kits Cabinet construction 39 ...

Page 40: ...Stage 1 Installation of common parts 40 Cabinet construction ...

Page 41: ...Stage 2 Installation of LCL side plates and common AC bus Cabinet construction 41 ...

Page 42: ...Stage 3 Installation of brackets for Flat PLS holder 42 Cabinet construction ...

Page 43: ...Stage 4A BLCL 15LC 7 AC connection and fuse busbars installation Cabinet construction 43 ...

Page 44: ...Stage 4B BLCL 24LC 7 AC connection and fuse busbars installation 44 Cabinet construction ...

Page 46: ...Stage 6 LCL choke and LCL choke busbar installation 46 Cabinet construction ...

Page 50: ...Stage 9 Installation of LCL shroud kit 50 Cabinet construction ...

Page 52: ...Overview of kits 52 Cabinet construction ...

Page 53: ...Stage 1 Installation of common parts Cabinet construction 53 ...

Page 54: ...Stage 2 Installation of LCL side plates and common AC bus 54 Cabinet construction ...

Page 55: ...Stage 3 Installation of brackets for Flat PLS holder Cabinet construction 55 ...

Page 56: ...Stage 4 AC connection and fuse busbars installation 56 Cabinet construction ...

Page 58: ...Stage 6 LCL choke and LCL choke busbar installation 58 Cabinet construction ...

Page 61: ...Stage 9 Installation of LCL shroud kit Cabinet construction 61 ...

Page 65: ...Overview of kits Cabinet construction 65 ...

Page 66: ...Stage 1 Installation of common parts 66 Cabinet construction ...

Page 67: ...Stage 2 Side plate module mounting mechanics and quick connectors Cabinet construction 67 ...

Page 68: ...Stage 3 Flat PLS support kit for AC and common AC connection busbars 68 Cabinet construction ...

Page 69: ...Stage 4 Fan heat exchanger and cooling components Cabinet construction 69 ...

Page 70: ...Stage 5A Installation of DC busbars 70 Cabinet construction ...

Page 72: ...Stage 6 Module installation 72 Cabinet construction ...

Page 73: ...Stage 7 Installation of shrouding Cabinet construction 73 ...

Page 77: ...Overview of kits Cabinet construction 77 ...

Page 78: ...Stage 1 Installation of common parts 78 Cabinet construction ...

Page 79: ...Stage 2 Side plate module mounting mechanics and quick connectors Cabinet construction 79 ...

Page 80: ...Stage 3 Flat PLS support kit for AC and common AC connection busbars 80 Cabinet construction ...

Page 81: ...Stage 4 Fan heat exchanger and cooling components Cabinet construction 81 ...

Page 82: ...Stage 5A Installation of DC busbars 82 Cabinet construction ...

Page 84: ...Stage 6 Module installation 84 Cabinet construction ...

Page 85: ...Stage 7 Installation of shrouding Cabinet construction 85 ...

Page 89: ...Overview of kits Cabinet construction 89 ...

Page 90: ...Stage 1 Installation of common parts 90 Cabinet construction ...

Page 91: ...Stage 2 Side plate module mounting mechanics and quick connectors Cabinet construction 91 ...

Page 92: ...Stage 3 Flat PLS support kit for AC and common AC connection busbars 92 Cabinet construction ...

Page 93: ...Stage 4 Fan heat exchanger and cooling components Cabinet construction 93 ...

Page 94: ...Stage 5A Installation of DC busbars 94 Cabinet construction ...

Page 96: ...Stage 6 Module installation 96 Cabinet construction ...

Page 97: ...Stage 7 Installation of shrouding Cabinet construction 97 ...

Page 98: ...98 ...

Page 114: ...114 ...

Page 125: ...a b c Maintenance 125 ...

Page 180: ...180 ...

Page 206: ...206 ...

Page 208: ...Frame R8i module 208 Dimension drawings ...

Page 209: ... Quick connector Dimension drawings 209 ...

Page 210: ...LCL filter components Grid side choke BLCL 15LC 7 and BLCL 24LC 7 210 Dimension drawings ...

Page 211: ... Grid side choke BLCL 25LC 7 Dimension drawings 211 ...

Page 212: ... Converter side choke BLCL 15LC 7 and BLCL 24LC 7 212 Dimension drawings ...

Page 213: ... Converter side choke BLCL 25LC 7 Dimension drawings 213 ...

Page 214: ... Capacitor www tdk electronics tdk com 214 Dimension drawings ...

Page 276: ...276 ...