Electrical installation 99

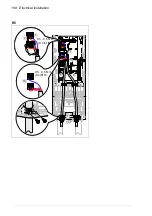

Notes:

1)

Current [0(4)…20 mA,

R

in

= 100 ohm] or voltage [ 0(2)…10 V,

R

in

> 200 kohm] input selected

with switch S1 (AI1). Change of setting requires changing the corresponding parameter.

2)

Current [0(4)…20 mA,

R

in

= 100 ohm] or voltage [ 0(2)…10 V,

R

in

> 200 kohm] input selected

with switch S2 (AI2). Change of setting requires changing the corresponding parameter.

3)

Total load capacity of the Auxiliary voltage 24V (X2:10) is 6.0 W (250 mA / 24 V)

minus the power taken by the option modules installed on the board.

4)

AI1 is used as a speed reference if vector control is selected.

5)

In scalar control (default): See

Menu - Primary settings

-

Start, stop, reference

-

Constant

frequencies

or parameter group 28 Frequency reference chain.

In vector control: See

Menu - Primary setting - Start, stop, reference

-

Constant speeds

or

parameter group 22 Speed reference selection.

6)

In scalar control (default): See

Menu - Primary settings

-

Ramps

or parameter group 28

Frequency reference chain.

In vector control: See

Menu - Primary settings

-

Ramps

or parameter group 23 Speed

reference ramp.

7)

Connected with jumpers at the factory.

8)

Note:

Use shielded twisted-pair cables for digital signals.

9)

Ground the outer shield of the cable 360 degrees under the grounding clamp on the

grounding shelf for the control cables.

Further information on the usage of the connectors and switches is given in the sections below.

See also section

on page

.

DI3 DI4

Operation/Parameter

Scalar control (default)

Vector control

0

0

Set frequency through AI1

Set speed through AI1

1

0

28.26 Constant frequency 1

22.26 Constant speed 1

0

1

28.27 Constant frequency 2

22.27 Constant speed 2

1

1

28.28 Constant frequency 3

22.28 Constant speed 3

DI5 Ramp

set

Parameters

Scalar control (default)

Vector control

0

1

28.72 Freq acceleration time 1

23.12 Acceleration time 1

28.73 Freq deceleration time 1

23.13 Deceleration time 1

1

2

28.74 Freq acceleration time 2

23.14 Acceleration time 2

28.75 Freq deceleration time 2

23.15 Deceleration time 2

Summary of Contents for ACS580-01 drives

Page 1: ...ABB general purpose drives Hardware manual ACS580 01 drives 0 75 to 250 kW...

Page 4: ......

Page 11: ...Table of contents 11 Document library on the Internet 225...

Page 12: ...12 Table of contents...

Page 72: ...72 Planning the electrical installation...

Page 79: ...Electrical installation 79 R6 R9 3 3 4...

Page 132: ...132 Maintenance and hardware diagnostics...

Page 168: ...168 Dimension drawings Frame R0 IP21 3AXD10000257110...

Page 169: ...Dimension drawings 169 Frame R0 IP55 3AXD10000341562...

Page 170: ...170 Dimension drawings Frame R1 IP21 3AXD10000257188...

Page 171: ...Dimension drawings 171 Frame R1 IP55 3AXD10000336766...

Page 172: ...172 Dimension drawings Frame R2 IP21 3AXD10000257203...

Page 173: ...Dimension drawings 173 Frame R2 IP55 3AXD10000341578...

Page 174: ...174 Dimension drawings Frame R3 IP21 3AXD10000257219...

Page 175: ...Dimension drawings 175 Frame R3 IP55 3AXD10000335424...

Page 176: ...176 Dimension drawings Frame R4 IP21 3AXD10000332430...

Page 177: ...Dimension drawings 177 Frame R4 IP55 3AXD10000427933...

Page 178: ...178 Dimension drawings Frame R5 IP21 3AXD10000412280...

Page 179: ...Dimension drawings 179 Frame R5 IP55 3AXD10000415964...

Page 180: ...180 Dimension drawings Frame R6 IP21 3AXD10000258705...

Page 181: ...Dimension drawings 181 Frame R6 IP55 3AXD10000330667...

Page 182: ...182 Dimension drawings Frame R7 IP21 3AXD10000258995...

Page 183: ...Dimension drawings 183 Frame R7 IP55 3AXD10000330932...

Page 184: ...184 Dimension drawings Frame R8 IP21 3AXD10000287670...

Page 185: ...Dimension drawings 185 Frame R8 IP55 3AXD10000332446...

Page 186: ...186 Dimension drawings Frame R9 IP21 3AXD10000287428...

Page 187: ...Dimension drawings 187 Frame R9 IP55 3AXD10000334310...

Page 188: ...188 Dimension drawings...

Page 196: ...196 Resistor braking...