•

External wiring can supply dangerous voltages to the relay outputs of the control units

of the drive.

•

The Safe torque off function does not remove the voltage from the main and auxiliary

circuits. The function is not effective against deliberate sabotage or misuse.

Optical components

WARNING!

Obey these instructions. If you ignore them, damage to the equipment can occur.

•

When you unplug the fibre optic cables, always hold the connector, not the cable itself.

•

Do not touch the ends of the fibers with bare hands as the ends are extremely sensitive

to dirt.

•

Do not bend the fiber optic cables too tightly. The minimum allowed bend radius is

35 mm (1.4”).

Printed circuit boards

WARNING!

Use a grounding wrist band when you handle printed circuit boards. Do not touch

the boards unnecessarily. The boards contain components sensitive to electrostatic

discharge.

■

Grounding

These instructions are for all personnel who are responsible for the grounding of the drive.

WARNING!

Obey these instructions. If you ignore them, injury or death, or equipment

malfunction can occur, and electromagnetic interference can increase.

•

If you are not a qualified electrician, do not do grounding work.

•

Always ground the drive, the motor and adjoining equipment. This is necessary for the

personnel safety. Proper grounding also reduces electromagnetic emission and

interference.

•

Make sure that the conductivity of the protective earth PE conductors is sufficient. See

the electrical planning instructions of the drive. Obey the local regulations.

•

Connect the power cable shields to protective earth terminals of the drive to make sure

of personnel safety.

•

Make a 360° grounding of the power and control cable shields at the cable entries to

suppress electromagnetic disturbances.

•

In a multiple-drive installation, connect each drive separately to the protective earth

(PE) busbar of the power supply.

Note:

•

You can use power cable shields as grounding conductors only when their conductivity

is sufficient.

•

IEC/EN 61800-5-1 (section 4.3.5.5.2.) requires that as the normal touch current of the

drive is higher than 3.5 mA AC or 10 mA DC, you must use a fixed protective earth (PE)

connection. The minimum size of the protective earthing conductor must comply with

the local safety regulations for high protective earthing conductor current equipment.

Safety instructions 15

Summary of Contents for ACQ80-04 Series

Page 1: ...ABB DRIVES FOR WATER ACQ80 04 drives 0 75 to 160 kW 1 0 to 215 hp Hardware manual...

Page 2: ......

Page 4: ......

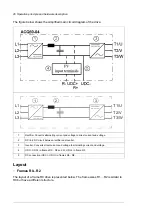

Page 18: ...18...

Page 24: ...24...

Page 38: ...38...

Page 50: ...50...

Page 64: ...64...

Page 98: ...98...

Page 110: ...110...

Page 140: ...Frame R3 IP20 140 Dimension drawings...

Page 146: ...146...

Page 162: ...162...

Page 168: ......