32

MicroTouch™ ClearTek™ II Integration Guide

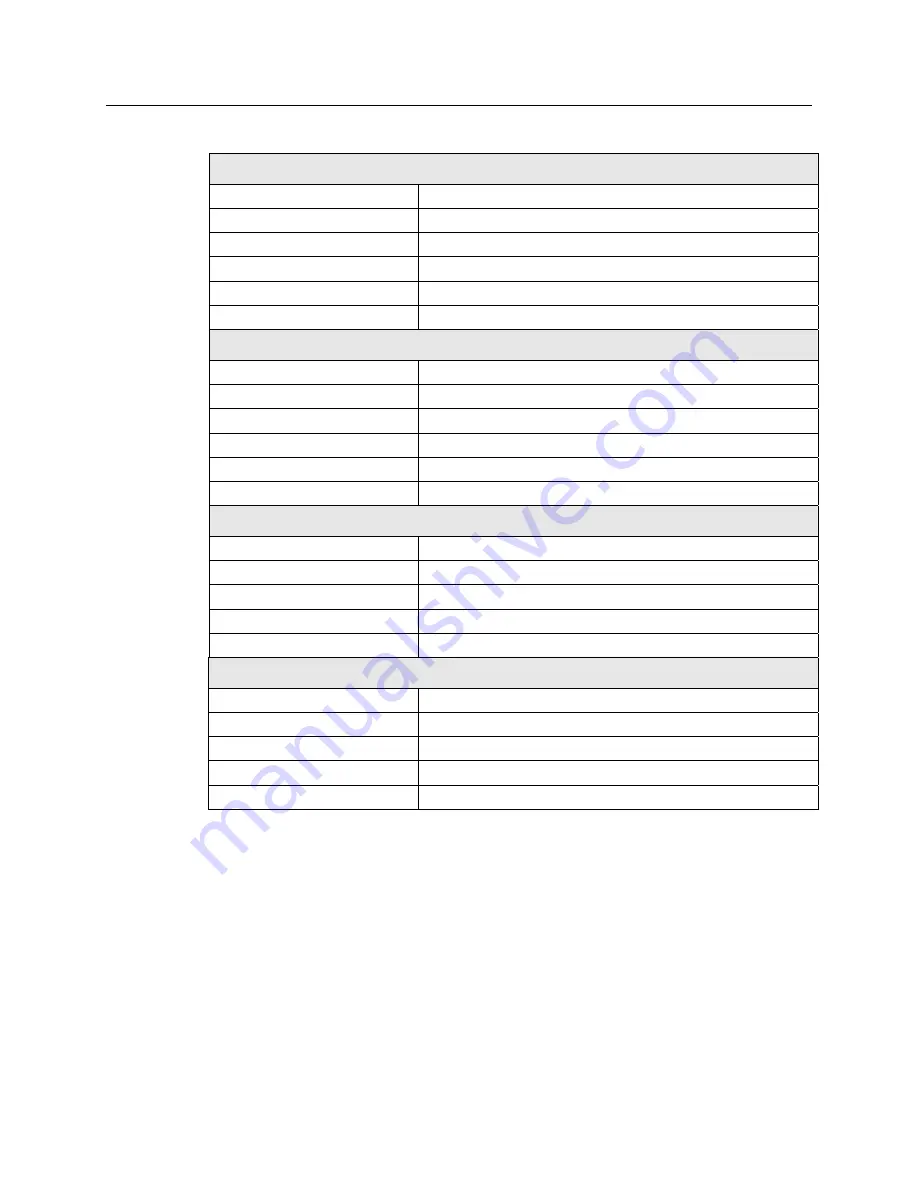

Table 1. ClearTek II Compatible Controllers

EX II 1700SC series

Communications protocol

Serial RS-232

Documentation

EX II Serial Controller Reference Guide (29087)

Form factor

Cased: 3.75 in (95 mm) by 2.5 in (64 mm) by 0.84 in (21 mm)

Uncased: 3.5 in (89 mm) by 2.25 in (57 mm) by 0.3 in (8 mm)

Touch screens supported

ClearTek II touch screens with NOVRAM cable adapters

Installation options

Internal (uncased) or external (cased)

EX II 5700UC series

Communications protocol

USB 1.1

Documentation

EX II USB Controller Reference Guide (29489)

Form factor

Cased: 3.75 in (95 mm) by 2.5 in (64 mm) by 0.84 in (21 mm)

Uncased: 3.5 in (89 mm) by 2.25 in (57 mm) by 0.3 in (8 mm)

Touch screens supported

ClearTek II touch screens with NOVRAM cable adapters

Installation options

Internal (uncased) or external (cased)

EX II 7700SC series

Communications protocol

Serial RS232

Documentation

EX II Serial Controller Reference Guide (29087)

Form factor

1.3 in (33 mm) by 2.44 in (62 mm) by 0.32 in (8.1 mm)

Touch Screens supported:

Standard ClearTek II touch screens

Installation options

Internal only

EX II 7700UC series

Communications protocol

USB 1.1

Documentation

EX II USB Controller Reference Guide (29489)

Form factor

1.3 in (33 mm) by 2.44 in (62 mm) by 0.32 in (8.1 mm)

Touch Screens supported

Standard ClearTek II touch screens

Installation options

Internal only

Disassembling the Chassis

1. Remove the screws securing the display control panel cover to the chassis. Be sure to

save and label these screws for reassembly.

2. Take a moment to inspect the display’s internal hardware before you disconnect any

wires.

a.

Note where each wire is attached and how each wire is routed.

b.

Label each wire. Labeling the wires makes reassembling easier.

c.

Most LCD display manufacturers connect the major components with detachable

cables that have keyed connectors and labels. In addition, cables are of such

lengths that they usually connect to only one place. However, not all displays

3M Touch Systems Proprietary Information

Summary of Contents for MicroTouch ClearTek II

Page 20: ......