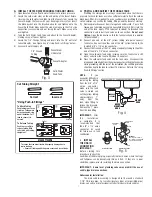

Drilling hole through Porcelain/Enamel/Ceramic Sinks

If you are reading this section, professional installation is highly

recommended.

Recommended Tools:

• Variable Speed Drill

• Porcelain Cutter Tool Set (7/8” Size)

• Plumber’s Putty

Note:

It is important to understand this procedure.

1. The glassy layer of porcelain/enamel/ceramic must be scored

through to the metal base, creating a disk.

2. This disk must be removed while protecting the surrounding deco-

rative coating against chipping or fracturing.

3. The base metal must be drilled through to complete the hole.

Procedure:

1. Mark center for 7/8” hole.

2. Form a dam of shallow putty around hole location and fill with

enough water to lubricate carbide drill bit.

3. Carefully drill pilot hole through porcelain/enamel/ceramic and base

metal using a carbide pilot drill bit. Always operate drill with light

pressure at slow speed (300 - 400 rpm).

4. Drill porcelain/enamel/ceramic using special 7/8” cutting tool,

making certain a complete ring has been cut through to the sink’s

metal base.

5. Change to metal cutting drill bit and drill out the center of the ring,

making sure not to contact other rim of decorative coating. Cut

through metal sink base.

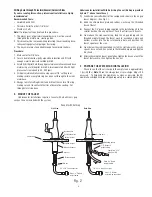

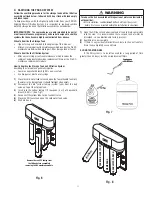

E. MOUNT THE FAUCET

Undercounter installations require a faucet with a built-in air gap

such as the one included with the system.

Undercounter Installation With An Air Gap Faucet (Air Gap is provided

by hole 1” above faucet base):

1)

Familiarize yourself with all of the components shown in the air gap

faucet diagram. (See Fig. 2)

2)

Slide the chrome base plate and rubber washer up the threaded

base of faucet.

3)

Connect the 1/4” green tubing supplied in the installation kit to the

smaller barb on the air gap faucet. Push it on firmly until it seats.

4)

From above the sink counter-top, feed the air gap tubing and the

threaded nipple through the faucet washer, escutcheon plate and

bottom washer into the faucet mounting hole and position the

faucet spout over the sink.

5)

From below the sink/countertop, install the slotted washer, plastic

spacer, base nut and hex nut onto the threaded nipple and tighten

it by hand.

6)

After rechecking the faucet orientation, tighten the base nut until the

faucet feels secure, then tighten the hex nut.

F. PREPARE THE SYSTEM FOR INSTALLATION

Check to see that the air charge in the empty tank is approximately

7 psi (48 kPa).

Note:

Check the storage tank air pre-charge. Adjust it if

necessary. To help keep the membrane as clean as possible, the RO

membrane cartridge has been shipped separately in a sealed plastic bag.

6

Fig. 2

Faucet with Air Gap

Side View

Back View

Air Gap hole

1/4” Standard

green tubing

Special red “SFC”

tube from RO

Black 3/8” Reject

tubing to drain

Blue 3/8” Product

water tubing connection

Blue 3/8” Product

water tubing

Faucet washer

Countertop

Bottom washer

Escutcheon plate

Mounting spacer

Threaded nipple

Hex nut

Slotted washer

Base nut

Mounting spacer

1/4” x 3/8” Tube Connector

1/4” x 3/8” Tube Connector