3D Systems, Inc.

12

p/n: 15-D99, rev. C

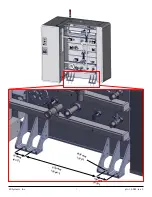

3.10 Chiller

Supplied by: 3D Systems

Installed by: 3D Systems

The chiller is used to regulate the temperature of the laser components.

A. Physical dimensions

• Weight:

40 kg (88 lbs)

• Dimensions (W x D x H):

377 x 521 x 650 mm (15 x 21 x 26 in)

B. Electrical - supplied from facility power

• Operating voltage: single phase 200 - 230 VAC (US: may be 2 phase)

• Frequency: 50 Hz / 60 Hz

• Circuit protection: 15 A

• 1 phase + n PE electrical cable.

To be supplied by customer

.

C. Cooling water

The chiller is connected to the DMP Flex 350 system with flexible hoses. Check the facility water to ensure it is not dirty, slimy

and no foreign matter is found before filling the chiller. Make sure the water is within conditions shown in the table below.

ITEM

STANDARD VALUE

CIRCULATING FLUID

FACILITY WATER

Standards

pH (at 25°C)

6.0 to 8.0

6.5 to 8.2

Electric conductance (at 25°C)

1 μS/cm and higher

100 to 800 μS/cm

Chloride ions

ppm

50 or less

200 or less

Sulfate ions

ppm

50 or less

200 or less

Acid consumption

ppm

50 or less

100 or less

Total hardness

ppm

70 or less

200 or less

Calcium hardness

ppm

50 or less

150 or less

Ionic silica

ppm

30 or less

50 or less

For

reference

Iron

ppm

0.3 or less

1.0 or less

Copper

ppm

0.1 or less

0.3 or less

Sulfide ions

ppm

Not detected

Not detected

Ammonium ions

ppm

0.1 or less

1.0 or less

Residual chlorine

ppm

0.3 or less

0.3 or less

Free carbon dioxide

ppm

4.0 or less

4.0 or less

D.

Cooling fluid additives

The chiller requires a mixture of tap water and a cooling fluid additive. Recommended cooling fluid additives are:

Hexid A4,

ControXid1642, Nalco CCL100, Cool flow IGE, Dowcal 100 and opti. The correct mixture of tap water and cooling fluid

additives must be according to 3rd party supplier guidelines.

Caution: These cooling fluid additives need to be supplied by the customer.

E. Noise emissions

• 75 dB