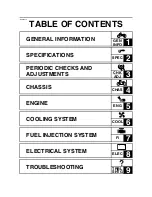

Summary of Contents for 2004 YP400

Page 1: ...2004 YP400 S 5RU1 AE1 SERVICE MANUAL ...

Page 2: ......

Page 8: ......

Page 9: ...GEN INFO 1 ...

Page 11: ...GEN INFO ...

Page 28: ...SPEC 2 ...

Page 30: ...SPEC ...

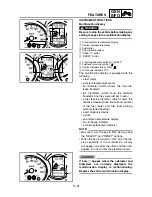

Page 77: ...CHK ADJ 3 ...

Page 137: ......

Page 138: ...CHAS 4 ...

Page 210: ......

Page 211: ...ENG 5 ...

Page 286: ...COOL 6 ...

Page 288: ...COOL ...

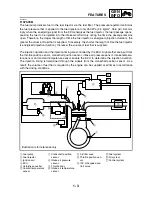

Page 299: ...FI 7 ...

Page 301: ...FI ...

Page 342: ...ELEC 8 ...

Page 378: ...8 34 ELEC LIGHTING SYSTEM ...

Page 404: ......

Page 405: ...TRBL SHTG 9 ...

Page 415: ......

Page 416: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN ...