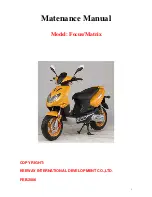

Summary of Contents for 2002 YB50

Page 1: ...2002 SERVICE MANUAL YN505RN AE1 ...

Page 7: ...GEN INFO 1 ...

Page 15: ......

Page 16: ...SPEC 2 ...

Page 27: ...INSP ADJ 3 ...

Page 49: ......

Page 50: ...ENG 4 ...

Page 91: ...CARB 5 ...

Page 102: ...CHAS 6 ...

Page 128: ......

Page 129: ...ELEC 7 ...

Page 156: ...LOC AVER 8 ...