GAS DRYER STACKING KIT INSTALLATION INSTRUCTIONS

(MAH6700 washer & MDG6700 dryer only)

GAS REQUIREMENTS

Use only Natural or LP (liquid petroleum) gases.

THE INSTALLATION MUST COMFORM WITH LOCAL CODES, OR IN THE

ABSENCE OF LOCAL CODES, WITH THE NATIONAL FUEL GAS CODE

ANSI/Z223.1, LATEST REVISION (FOR THE UNITED STATES), OR WITH THE

CAN/CGA-B149 INSTALLATION CODES (FOR CANADA).

A gas dryer is equipped with a burner orifice for operation on NATURAL gas.

If the

dryer is to be operated on LP gas, it must be converted for safe and proper

performance and must be converted by a qualified service technician.

Gas conversion kits from LP-to-natural or natural-to-LP are available and are to be

installed by a qualified service technician.

Each dryer will provide an input of 22,000 B.T.U. per hour.

A 1/2 inch gas supply line is recommended and must be reduced to connect to the

3/8 inch gas line on the dryer.

The National Fuel Gas Code requires that an accessible, approved manual gas

shut off valve be installed within 6 feet of the dryer.

Additionally, a 1/8 inch N.P.T. (National Pipe Thread) plugged tapping, accessible

for test gauge connection, must be installed immediately upstream of the gas

supply connection to the dryer.

The dryer must be disconnected from the gas supply piping system during any

pressure testing of the system.

The Flexing Gas Connector supplied with this kit must be uesd for this installation.

In all applications with the dryer stacked on a washer, the Maytag Flexing Gas Line

Connector(p/n34001465)must be used.

Failure to comply may result in gas line failure or gas leaks.

NOTE

:

Any pipe joint compound used must be resistant to the action of any

liquified petroleum gas.

GAS IGNITION

-

The dryer uses an automatic ignition system to ignite the burner.

There is no constant burning pilot.

DC68-01052F REV(0.1)

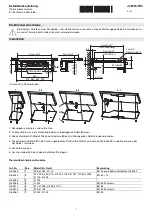

Step 1:

Place cover (cloth, cardboard, or carpeting) on floor

surface to avoid damage.

Step 2:

Lay the dryer on its side (not front or back).

Step 7:

Bottom view of the dryer after

assembling the Stacking Support Guides to

the dryer base.

Step 3:

Unscrew and disassemble the

four leg assemblies.

Step 4:

Disassemble each leg from the bracket.

Then flip the bracket over and remount onto the leg.

Step 5:

Reassemble each leg and bracket

into the dryer base.

Step 6:

Snap the Stacking Support Guides into the

rectangular holes in the dryer base and secure each

with two(2) Screws Phillips-pan head(6006-001174).

Hook

Caution

: Two people are required to lift the dryer on

to the washer.

Dryer

MODEL NO: MALGO27AXX