1

KB-3411JS

KB-3411JK

KB-3411JW

This is a supplemental Service Manual and is quite similar to the base models KB-3300JS/JK/JW; (S74R243KB330J). This

supplemental manual must be used in conjunction with the base model service manual for complete operation, service, safety

and replacement parts information.

WARNING TO SERVICE PERSONNEL:

This service manual is intended for use by persons having electrical and mechanical training and a level of

knowledge of these subjects generally considered acceptable in the appliance repair trade. Sharp Electronics

Corporation cannot be responsible, nor assume any liability, for injury or damage of any kind arising from the

use of this manual.

Microwave ovens contain circuitry capable of producing very high voltage and current. Contact with the following

parts may result in a severe, possibly fatal, electrical shock. (High Voltage Capacitor, High Voltage Power

Transformer, High Voltage Rectifier and Heat sink etc., and Magnetron, High Voltage Harness etc..)

S25R247KB341J

KB-3411JS

KB-3411JK

KB-3411JW

FREE STANDING RANGE

WITH MICROWAVE DRAWER

MODELS

SUPPLEMENTAL SERVICE MANUAL

TABLE OF CONTENTS

Page

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TO

AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY ................... INSIDE FRONT COVER

BEFORE SERVICING ...................................................................................................... INSIDE FRONT COVER

WARNING TO SERVICE PERSONNEL ............................................................................................................... 1

MICROWAVE MEASUREMENT PROCEDURE ..................................................................................................... 3

FOREWORD AND WARNING ................................................................................................................................ 5

PRODUCT SPECIFICATIONS ............................................................................................................................... 6

POWER CONNECTION ......................................................................................................................................... 8

ANTI-TIP DEVICE ............................................................................................................................................... 10

CONTROL LAYOUT ............................................................................................................................................ 11

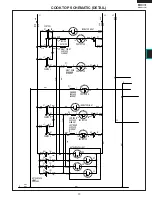

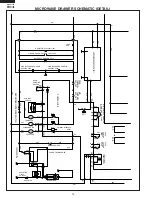

SCHEMATICS ..................................................................................................................................................... 12

TOUCH CONTROL PANEL ASSEMBLY ............................................................................................................. 16

OVEN/MICROWAVE DRAWER DISASSEMBLY ................................................................................................. 21

WIRING DIAGRAMS ........................................................................................................................................... 33

PRINTED WIRING BOARDS ............................................................................................................................... 39

PARTS LIST ........................................................................................................................................................ 44

PACKING AND ACCESSORIES ......................................................................................................................... 55

This document has been published to be used for after sales service only. The contents are subject to change without notice.

SHARP ELECTRONICS CORPORATION

KB-3411JS pictured