1. Precautions

2. Product Features and Specifications

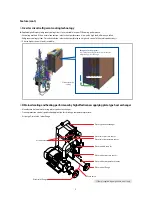

3. Disassembly and Reassembly

4. Troubleshooting

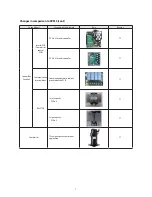

5. PCB Diagram and Parts List

6. Wiring Diagram

7. Cycle Diagram

8. Key Options

9. Trial Operation

CONTENTS

DVM CHILLER

DVM CHILLER

AG042KSVANH/AG056KSVANH/AG070KSVANH

AG042KSVGNH/AG056KSVGNH/AG070KSVGNH

SYSTEM AIR CONDITIONER

Summary of Contents for AG042KSVANH

Page 111: ...107 5 6 ASSY PCB MAIN HUB Model All models name is commonness DC 1 2 3 4 5 6 7 8 9 10 11 12 ...

Page 113: ...109 ASSY PCB MAIN HUB cont Model All models name is commonness AC 1 1 2 3 4 5 6 7 8 9 10 11 ...

Page 115: ...111 5 7 ASSY PCB INVERTER PF 8 Model AG042 056KSV666 Series 4 2 3 5 1 8 9 7 6 ...

Page 117: ...113 ASSY PCB INVERTER PF 9 cont Model AG070KSV666 Series 10 8 4 9 7 6 11 12 13 1 2 3 5 ...