© 2013 Panasonic Co., Ltd. All rights reserved.

Unauthorized copying and distribution is a violation

of law.

Order Number PHARW1304002CE

Refrigerator-Freezer

Model No.

NR-B32FX3

NR-B32FW3

NR-BG32FX3

NR-BG32FW3

Product Color W: White, X: Stainless

Destination

E: Europe Continental, B: U.K. ,

G: Germany

TABLE OF CONTENTS

PAGE

PAGE

1 Safety Precautions

-----------------------------------------------

2 Specifications

-----------------------------------------------------

3 General/Introduction

--------------------------------------------

4 Features

-------------------------------------------------------------

5 Technical Descriptions

----------------------------------------

6 Location of Controls and Components

------------------

7 Installation Instructions

---------------------------------------

8 Test Mode

----------------------------------------------------------

9 Service Mode

-----------------------------------------------------

10 Troubleshooting Guide

---------------------------------------

11 Disassembly and Assembly Instructions

---------------

12 Maintenance

------------------------------------------------------

13 Dimensions

-------------------------------------------------------

14 Schematic Diagram

--------------------------------------------

15 Exploded View and Replacement Parts List

-----------

Summary of Contents for NR-B32FX3

Page 6: ...6 3 General Introduction 3 1 Flow of Refrigerant And Air ...

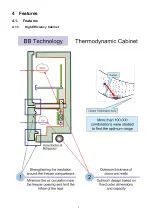

Page 7: ...7 4 Features 4 1 Features 4 1 1 High Efficiency Cabinet ...

Page 8: ...8 4 1 2 Storage Solution ...

Page 9: ...9 4 1 3 Refrigerator Compartment 4 1 4 Hygiene Active and Multi Airflow ...

Page 10: ...10 4 1 5 Vegetable Case 4 1 6 Vitamin Safe ...

Page 11: ...11 4 1 7 Hygiene Active ...

Page 18: ...18 6 2 Components ...

Page 19: ...19 7 Installation Instructions 7 1 Installation Instructions ...

Page 20: ...20 ...

Page 21: ...21 7 2 Setting the temperature ...

Page 22: ...22 7 3 Using the handy functions ...

Page 27: ...27 10 Troubleshooting Guide 10 1 FC and PC not cooling at all Compressor does not run ...

Page 28: ...28 10 2 PC is not cooling or poor cooling FC cooling condition is normal ...

Page 29: ...29 10 3 FC is poor cooling Compressor run ...

Page 30: ...30 10 4 VC is poor cooling or excessive cooling ...

Page 48: ...48 12 Maintenance ...

Page 49: ...49 ...

Page 50: ...50 ...

Page 51: ...51 13 Dimensions 13 1 Outside ...

Page 52: ...52 13 2 Inside ...