CM602-L

Reference Manual

Page 1-1

1.

1. GENERAL DESCRIPTION

This chapter describes the following items.

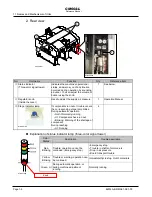

Names and mechanisms of units

This describes the names and functions of each unit using the illustrations.

Production process

This describes the placement process step by step.

Specifications

This describes the specifications of the machine and applicable boards.

∗

This machine can use the high-speed head (12 nozzles / 8 nozzles) and the multi-functional

head.

EJM4A-E-RMA01-A00-01