Summary of Contents for XR900 Series

Page 1: ...XR900 Series Mass Storage Subsystem User s Manual MCPIOSA UM2 ...

Page 9: ...x ...

Page 11: ...xii ...

Page 43: ...Operating Instructions 3 10 3 ...

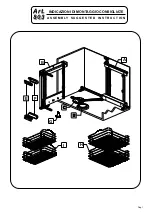

Page 53: ...Removal Replacement Procedures 4 10 4 Figure 4 4 Drive Module Release Latches 11060 00 9409 ...

Page 58: ...Support Information 5 4 5 ...