Reviews:

No comments

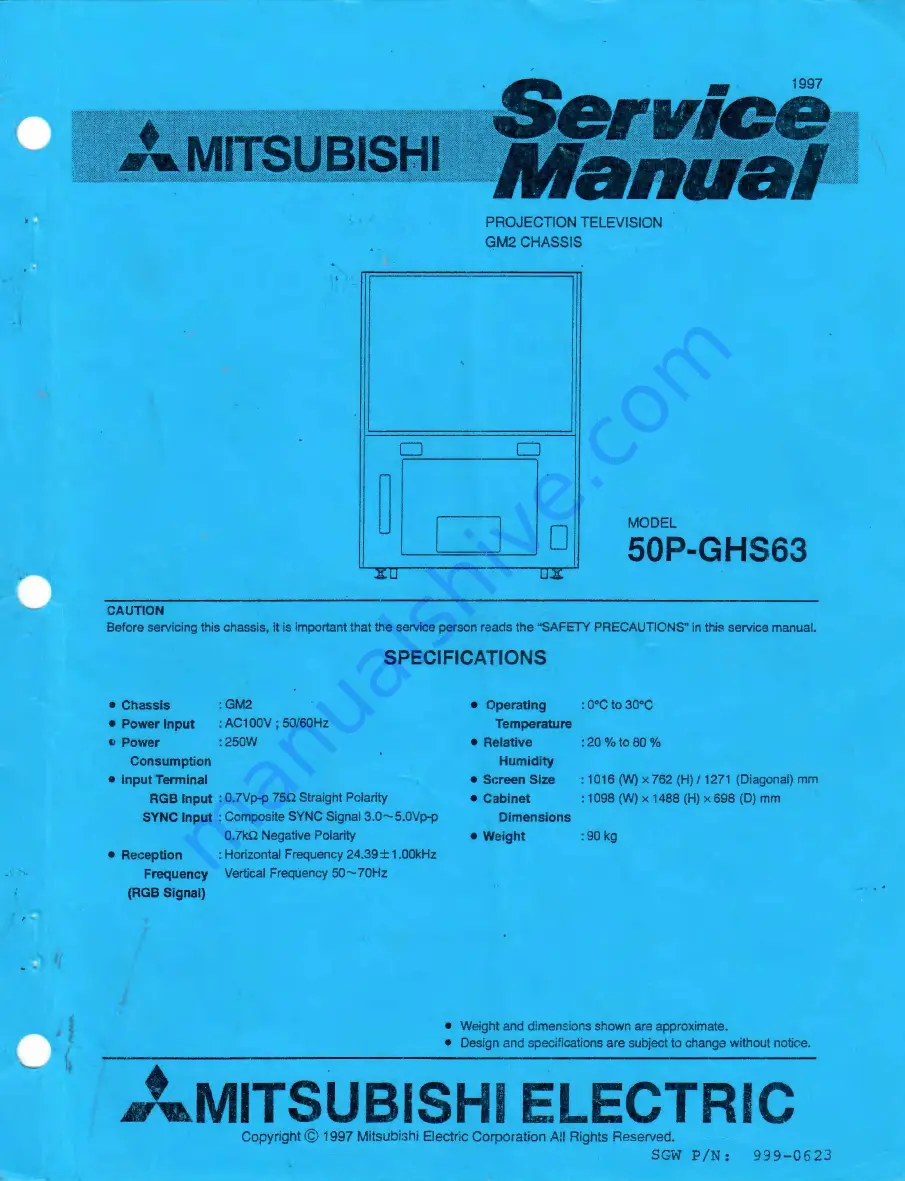

Related manuals for 50P-GHS63

PT-53TWD63

Brand: Panasonic Pages: 41

PT52DL10 - 52" DLP REAR PJ HDTV

Brand: Panasonic Pages: 76

HC-P4241W

Brand: Samsung Pages: 63

HCM4216W

Brand: Samsung Pages: 67

HC-P4241W

Brand: Samsung Pages: 59

HL-P5685W

Brand: Samsung Pages: 95

SP-43Q5HL

Brand: Samsung Pages: 6

HL61A750A1FXZA

Brand: Samsung Pages: 101

Model B

Brand: Da-Lite Pages: 2

DSJ-6000LN

Brand: Daewoo Pages: 74

51MP6100D - 51" Widescreen Hd Ready Tv

Brand: Magnavox Pages: 38

Magnavox 60P 8241

Brand: Magnavox Pages: 54

51MP6100D - 51" Widescreen Hd Ready Tv

Brand: Magnavox Pages: 38

50ML8205D - 50" Hd Dlp™ Projection Tv

Brand: Magnavox Pages: 40

R45W47

Brand: Zenith Pages: 36

R50V26

Brand: Zenith Pages: 56

R56W36

Brand: Zenith Pages: 60

D60WLCD Series

Brand: Zenith Pages: 88