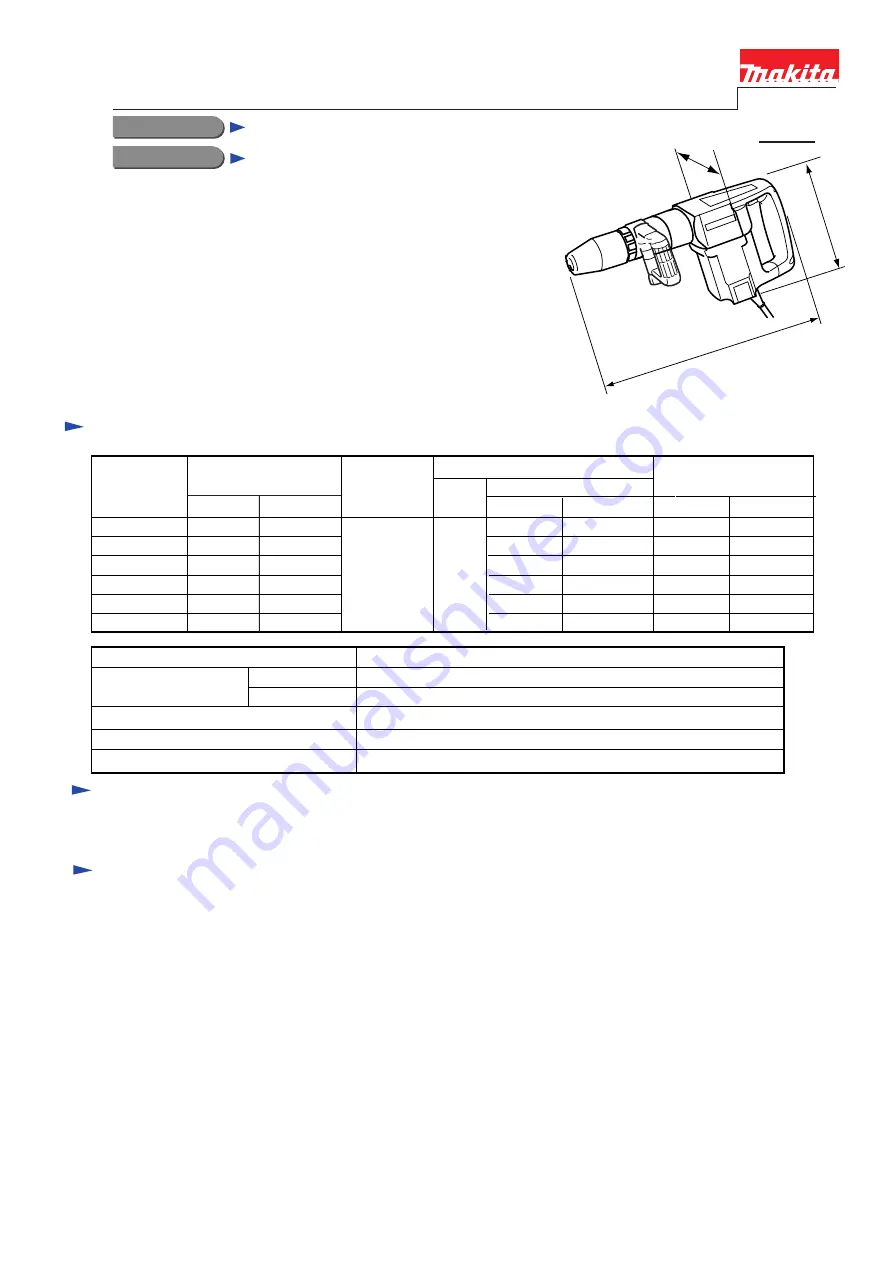

HM1202, HM1202C

Demolition Hammers

Continuous Rating (W)

Voltage (V)

Current (A)

Cycle (Hz) Input

Output

Max. Output(W)

100

15.0

110

120

220

7.3

230

7.0

240

6.7

550

1800

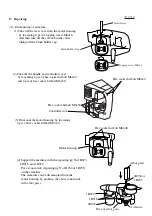

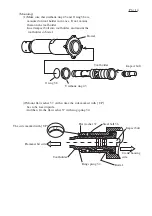

Bit-type

SDS-Max

HM1202C

950-1900 (bpm)

Blows per minute

HM1202

1900 (bpm)

Net Weight

9.3kg (20.5 lbs)

Cord Length

5m (16.4 ft)

Bit Grease

Bull-Point 280

The standard equipment for the tools shown may differ form country to country.

CONCEPTION AND MAIN APPLICATIONS

Specifications

Models No.

Product

T

ECHNICAL INFORMATION

Description

Standard equipment

Optional accessories

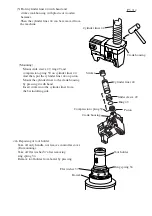

These demolition hammers are newly developped

as a 10 Kg hammer. (middel class between

HM1201 and HM1303 series models.)

Considerable strong demolishing power in this class,

However, softened reaction.

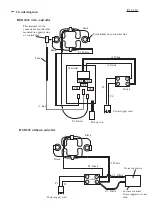

Model HM1202C : equipped with electronic control system

and variable speed control dial.

Model HM1202 : without the above features.

50/60

550

1800

550

1800

500

1600

500

1600

500

1600

HM1202 HM1202C

15.0

13.0

15.0

14.0

13.0

6.8

6.5

6.3

1,450

HM1202 HM1202C HM1202 HM1202C

750

750

750

700

700

700

1500

1500

1500

1600

1600

1600

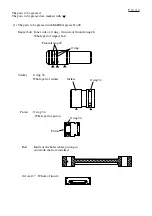

Size of shank

18mm (11/16")

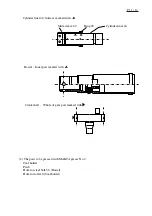

Bull Point 280

Bull Point 400

Cold Chisel 25x280

Cold Chisel 25x400

Scaling Chisel 50x400

Clay Spade 105x400

Hammer Grease

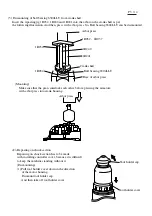

112mm(4-3/8")

258mm(10-1/8")

578mm(22-3/4")

P 1 / 14